Overall Equipment Effectiveness (OEE) to standard branżowy służący do pomiaru produktywności wytwarzania. Pokazuje, jak blisko jesteś do pełnego potencjału swojej linii produkcyjnej, łącząc trzy kluczowe wskaźniki (KPI):

-

Dostępność: Jak często twoje maszyny pracują zgodnie z planem, uwzględniając zarówno planowane, jak i nieplanowane przestoje.

-

Wydajność: Jak efektywnie pracują maszyny w porównaniu z ich maksymalną prędkością i możliwościami.

-

Jakość: Ile wyprodukowanych jednostek spełnia standardy jakości, bez potrzeby poprawek czy powstawania odpadów.

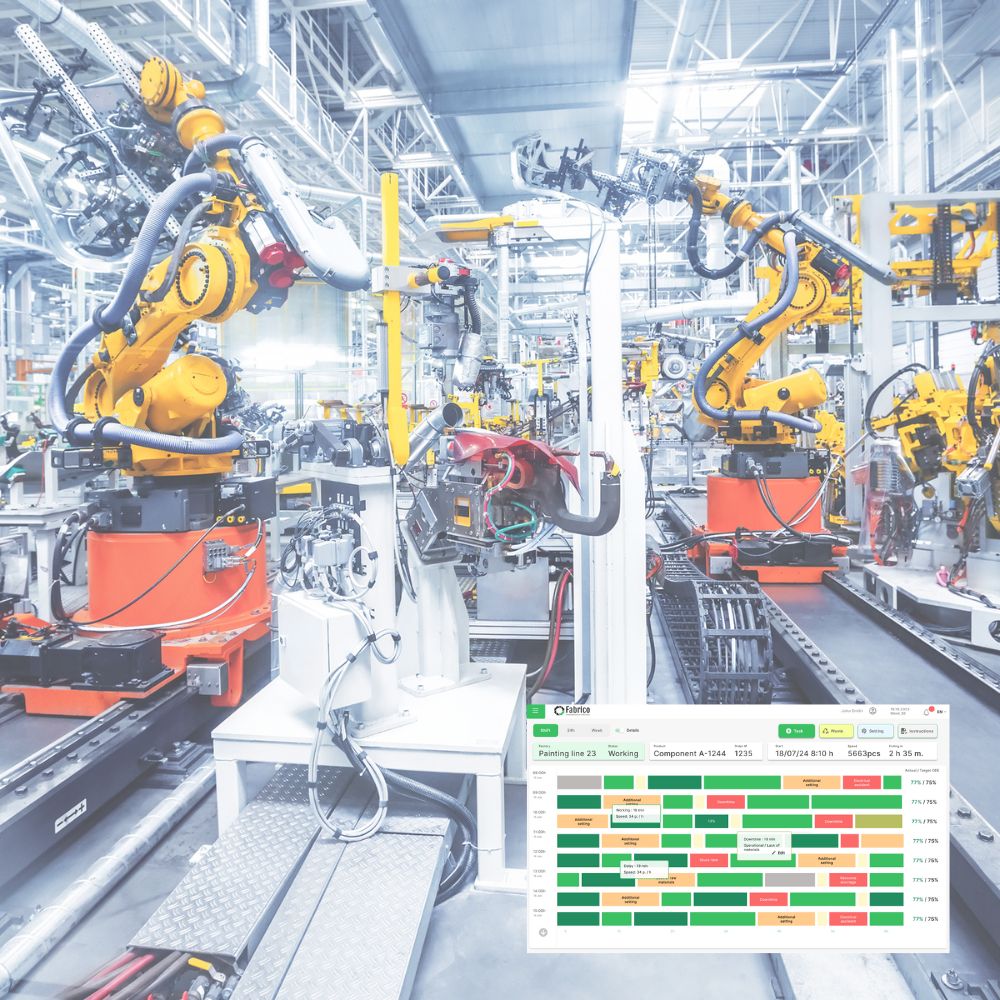

Tradycyjne systemy OEE często opierają się na fragmentarycznych danych lub raportach ręcznych, co ogranicza przejrzystość i opóźnia podejmowanie decyzji. Fabrico rozwiązuje ten problem dzięki połączonemu monitorowaniu OEE w czasie rzeczywistym, które pozwala wykrywać nieefektywności, ograniczać straty i łatwo zwiększać produktywność.