Fabrico is a dynamic, cloud-native MES/OEE framework purpose-built for the realities of automotive manufacturing. From high-mix, high-volume assembly lines to synchronized supplier networks, Fabrico helps automotive organizations overcome operational complexity and drive measurable results.

Automotive manufacturers face unique challenges—just-in-time production, complex supply chains, strict quality standards such as IATF 16949 and ISO/TS, and constant variant changes across models and configurations. Fabrico addresses these challenges head-on by delivering 15–25% improvements in OEE, enabling manufacturers to increase throughput, reduce waste, and maintain takt time across every shift.

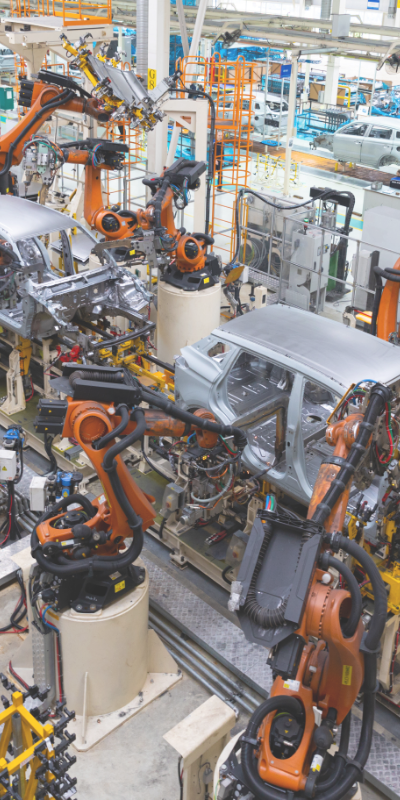

With seamless integration into ERP systems, PLCs, robotics, IoT devices, and computer vision systems, Fabrico creates a connected production ecosystem. Built-in traceability, quality gates, and defect prevention ensure compliance, while its scalable architecture supports global, multi-plant automotive operations.