To prepare for funding applications and ensure sustainable success, enterprises should follow a proven model consisting of several key steps.

Step 1: Assess Your Current State

The first and most crucial step is to conduct an honest and objective assessment of your current level of digitalization. This includes an analysis of existing processes, technologies and software in use, the connectivity between systems, and the digital skills of your employees.

The official tool recommended by the European Commission for this purpose is the Open DMAT - Digital Maturity Assessment. This is a self-assessment survey that helps any company identify its strengths and weaknesses.

You can conduct your self-assessment here: Open DMAT - Digital Maturity Assessment.

Step 2: Develop a Strategy

Based on the assessment, the enterprise must develop a clear and specific digitalization strategy. This strategy should include measurable goals (KPIs), clear milestones, and the necessary resources.

It is vital that the strategy is closely linked to the company's long-term business objectives—be it increasing productivity, reducing costs, or improving product quality. Technology should be implemented to solve a real business problem, not just because it is currently trendy.

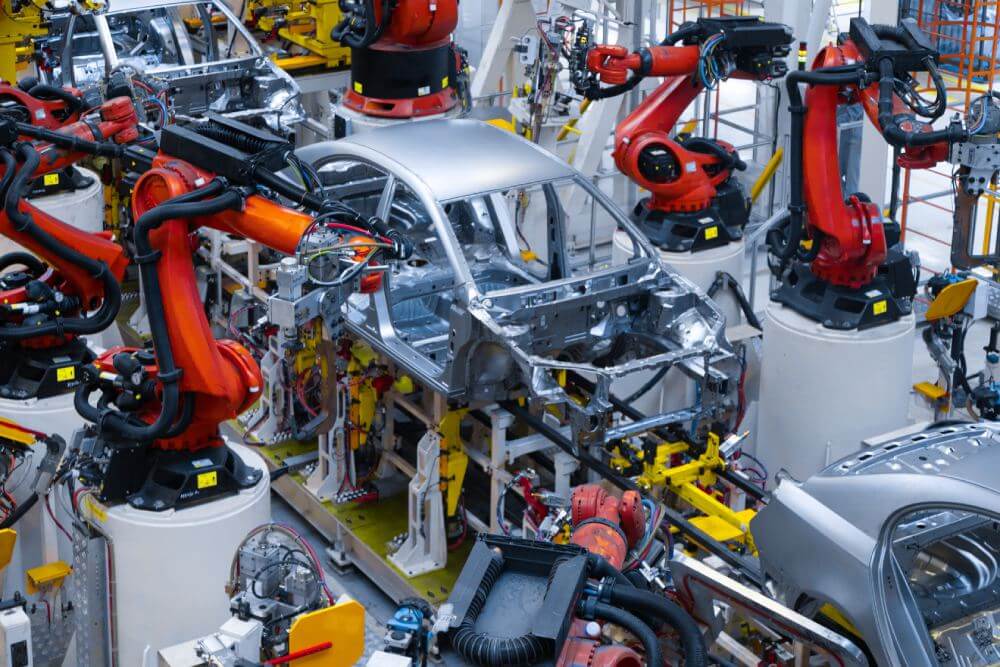

Step 3: Invest in the Right Technologies

Implementing Industry 4.0 requires significant investments in new technologies such as software systems for operational management (MES/MOM), the Industrial Internet of Things (IIoT), Artificial Intelligence (AI), and Big Data. The key is to select the most appropriate technologies that will help achieve your strategic goals. The investment must be justified and have a clear expected return (ROI).

Step 4: Partnerships and Collaboration

Digital transformation is a complex undertaking. It is highly recommended that enterprises do not try to do everything on their own but instead work with experts in the field of Industry 4.0. This includes partnering with technology providers who understand manufacturing processes, as well as collaborating with project preparation consultants and joining digital innovation hubs and clusters.

Step 5: Phased Implementation

Starting with pilot projects is a smart approach that mitigates risk. It allows the enterprise to test new technologies in a controlled environment, evaluate their effectiveness, and gather valuable lessons before deploying them on a larger scale. After a successful pilot project, the use of the technology can be expanded to other areas of the business.

Step 6: Continuous Monitoring and Adaptation

The digitalization process does not end with the software implementation. It is a dynamic process that requires continuous tracking of results and adaptation of the strategy. Enterprises must monitor key performance indicators and make adjustments when necessary to ensure the achievement of their goals.