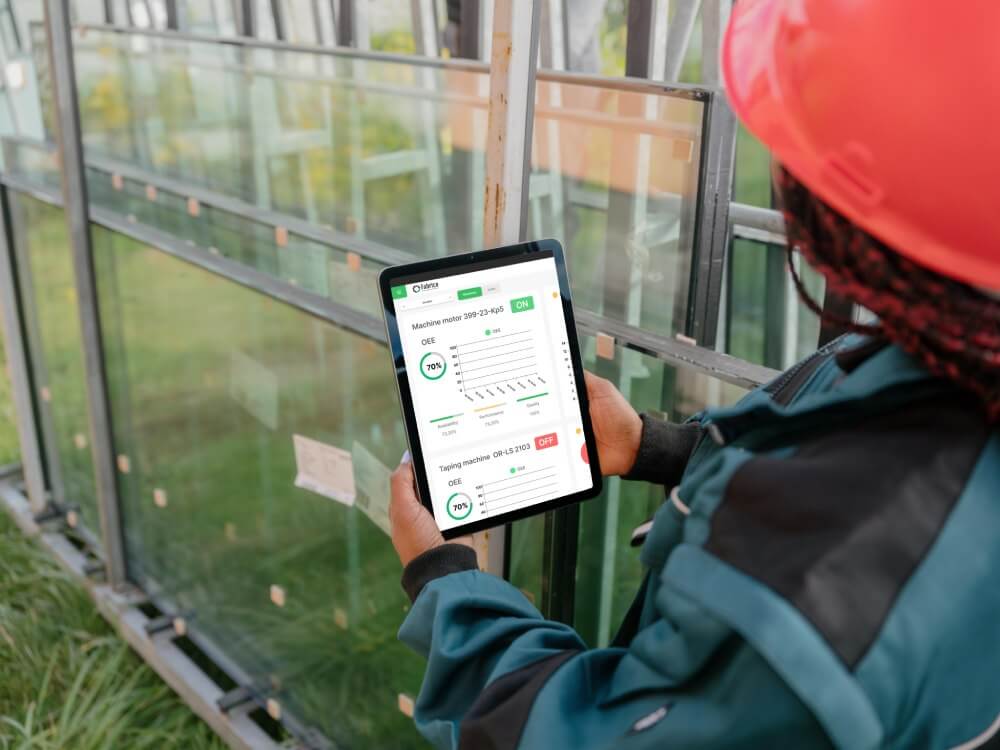

The first piece of the puzzle is Availability. It measures the percentage of time your machine was actually running compared to the time it was supposed to be running.

The Formula for Availability

The formula is a simple ratio: Availability = Run Time / Planned Production Time.

First, you need to define those two terms:

Let's Calculate It (Our Example)

Let's plug in our numbers:

-

Planned Production Time = 480 mins - 60 mins = 420 Minutes

-

Run Time = 420 mins - 40 mins = 380 Minutes

-

Availability = 380 / 420 = 90.4%

The Real-World Challenge: Where Did That "40 Minutes" of Downtime Really Come From?

Here's where manual tracking falls apart. That "40 minutes" looks clean in our example, but how was it measured on the factory floor? Did the operator, Tom, start a stopwatch the second the machine stopped? Or was it his best guess, written on a notepad an hour after the fact? Inaccurate downtime tracking is the biggest source of flawed OEE scores.