Key Takeaways

-

Real-time OEE shifts your team from being reactive historians who study yesterday's problems to proactive leaders who solve today's problems as they happen.

-

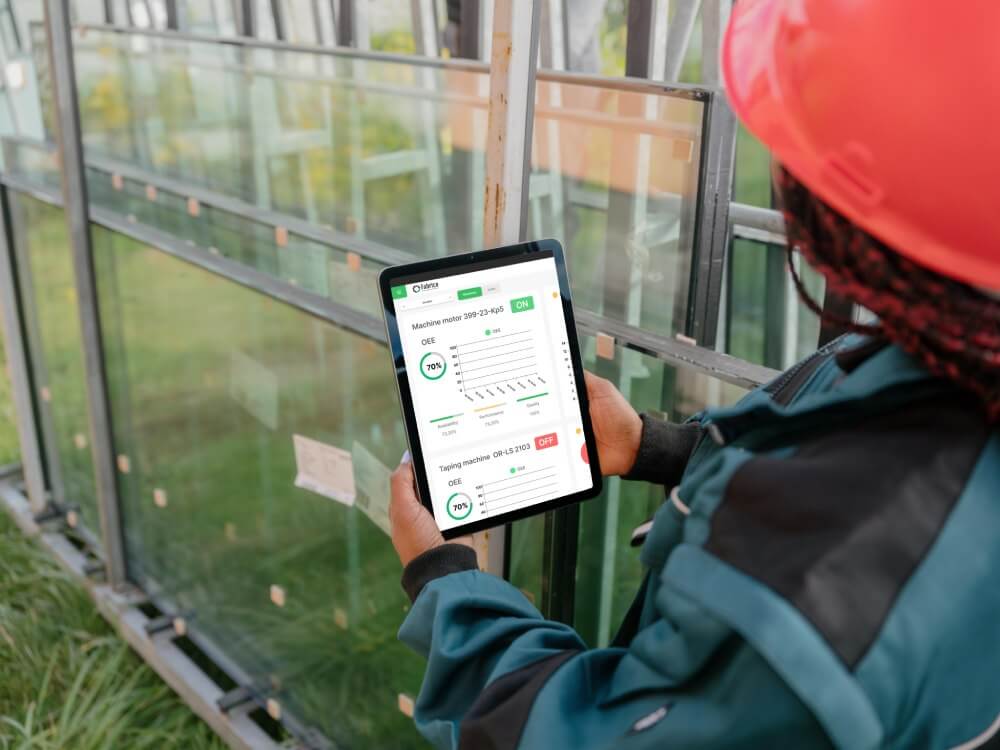

The magic isn't just in the live alert (the diagnosis). It's in the ability to instantly trigger a maintenance workflow (the cure) through an integrated CMMS.

-

By providing a single source of truth, real-time OEE stops unproductive debates in production meetings and focuses the conversation on strategic improvements.