If you walk into the Quality Manager's office, you will often see a specialized piece of software running on their screen—something like GAGEpack or CompuCal.

If you walk into the Maintenance Manager's office, you will see a different system—a CMMS tracking motors and belts.

This separation is a mistake.

Calibration is maintenance. Whether you are verifying a temperature sensor or greasing a bearing, it is an intervention on an asset to ensure performance.

Keeping these schedules in two different systems leads to "Double Downtime" (stopping the machine once for maintenance and again next week for calibration).

In 2025, many manufacturers are consolidating.

They are moving calibration out of the lab and into the CMMS.

Here are the 5 best software options to manage your calibration, ranging from integrated platforms to niche metrology tools.

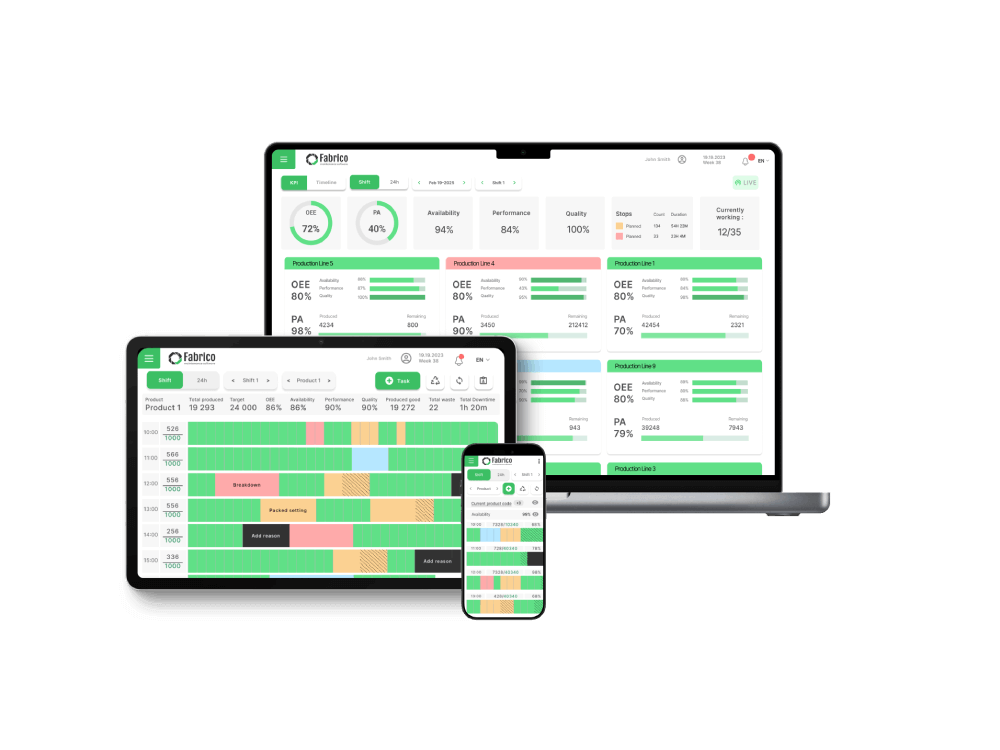

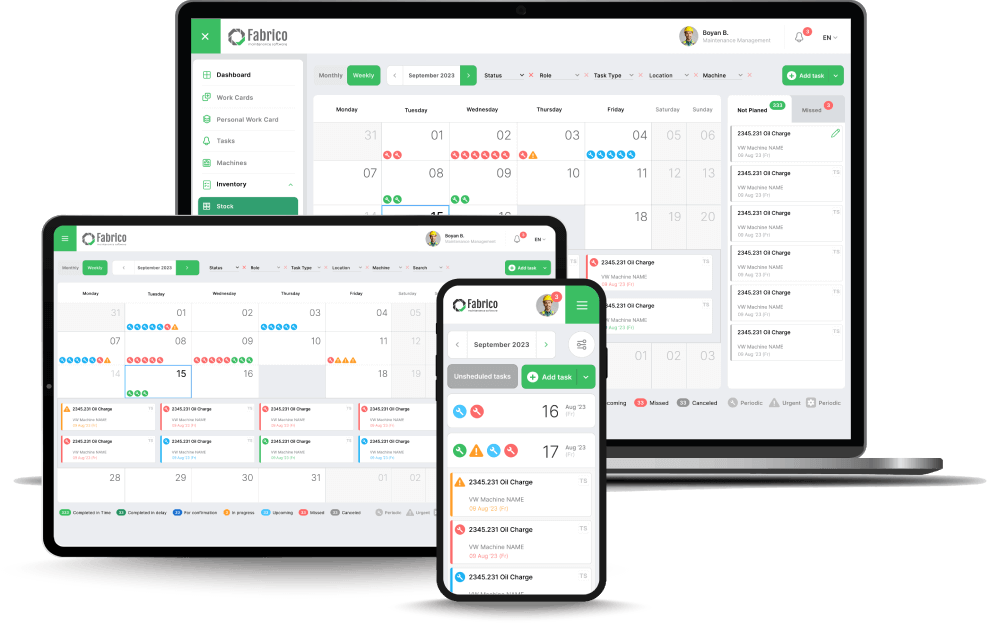

1. Fabrico: The "Integrated" Solution

Best For: Factories that want to combine Maintenance and Quality/Calibration in one app.

Fabrico challenges the idea that you need a separate tool for calibration. By treating calibration as a specific type of Work Order, Fabrico keeps all asset history in one place.

Why Manufacturers Switch to Fabrico:

-

Quantitative Data Fields: Most CMMS tools only allow "Pass/Fail." Fabrico allows you to define Measurement Fields with Min/Max tolerances. If the technician enters "45.5 PSI" and the limit is "45.0," the system automatically flags it as a Fail.

-

Traceability (21 CFR Part 11): Fabrico logs exactly who did the check, when (to the second), and locks the record. This satisfies ISO and FDA auditors without the complexity of a lab tool.

-

One Schedule: You can schedule the "Annual Calibration" and the "Annual Seal Replacement" on the same day, minimizing production interruptions.

-

OEE Link: Calibration directly affects product quality. Fabrico links the calibration status to the machine's OEE Quality score, giving you a complete picture of health.

The Verdict: If you want to stop paying for two subscriptions and unify your teams, Fabrico is the modern choice.

2. CompuCal

Best For: Dedicated Metrology Labs.

CompuCal is a heavyweight in the calibration space. It is designed specifically for regulated industries (Life Sciences) where calibration is the primary focus.

-

Pros: Deep functionality for managing "Standards" (the master instruments used to calibrate other instruments). It handles complex uncertainty calculations that general tools might miss.

-

Cons: It is a silo. It does not handle general maintenance (breaking pumps, conveyors) well. If you use CompuCal, you must buy a separate CMMS for the rest of the plant.

-

The Difference: Use CompuCal if you are running a lab. Use Fabrico if you are running a factory.

3. Beamex CMX

Best For: Teams using Beamex Calibrators (Hardware).

Beamex is famous for its "communicating calibrators"—hardware devices that plug into the sensor and talk to the software automatically.

-

Pros: Zero data entry errors. The software talks directly to the hardware tool. It is the gold standard for automation in process industries (Oil & Gas).

-

Cons: It is expensive and hardware-dependent. Unless you commit to the Beamex ecosystem, the software loses its primary advantage. It is also poor at managing general mechanical work orders.

-

The Difference: Beamex is for automation; Fabrico is for management.

4. GAGEpack (PQ Systems)

Best For: Managing loose gauges (micrometers, calipers).

If your primary challenge is tracking thousands of handheld calipers and thread gauges sitting in drawers, GAGEpack is the industry veteran.

-

Pros: Excellent for "Check-in/Check-out" tracking of tools. It manages the calibration cycles of portable tools very well.

-

Cons: It struggles with "Process Calibration" (calibrating a sensor fixed to a machine on the line). It is not designed to manage the asset itself, just the gauge.

-

The Difference: GAGEpack manages the tool; Fabrico manages the machine.

5. ProCalV5

Best For: Legacy compliance needs.

ProCal is a robust, older platform widely used in pharmaceutical manufacturing.

-

Pros: It has every compliance feature imaginable. It is battle-tested in highly regulated environments.

-

Cons: The interface is dated. It feels like software from the Windows 95 era. It is difficult to get modern technicians to adopt it for general maintenance tasks, reinforcing the silo between Quality and Maintenance.

-

The Difference: A lateral move for legacy compliance, but a downgrade in usability compared to modern SaaS.

Comparison Matrix: Integration vs. Specialization

| Feature |

Fabrico |

CompuCal |

Beamex |

GAGEpack |

| Primary Focus |

Maintenance & Calib. |

Lab Calibration |

Automated Calib. |

Gauge Tracking |

| Min/Max Tolerances |

✅ Yes |

✅ Yes |

✅ Yes |

✅ Yes |

| Work Orders |

✅ Full CMMS |

⚠️ Limited |

❌ No |

❌ No |

| OEE Integration |

✅ Native |

❌ No |

❌ No |

❌ No |

| User Interface |

Modern |

Traditional |

Technical |

Traditional |

Summary: Do you need a Lab tool or a Plant tool?

-

Stick with CompuCal or Beamex if: You are a dedicated Metrology Lab running thousands of calibrations a week with zero mechanical maintenance responsibility.

-

Choose GAGEpack if: You just need to track handheld calipers.

-

Choose Fabrico if: You are a Manufacturing Plant. If you want to manage your process sensors (Temperature, Pressure, Flow) alongside your motors and belts in a single, audit-ready system, Fabrico is the efficient choice.

Consolidate your software.

[Book a Demo with Fabrico] to see how we handle calibration tolerances inside a standard work order.