There is no worse feeling for a Maintenance Manager than diagnosing a breakdown, knowing exactly how to fix it, and then realizing the spare part isn't on the shelf.

It says "3 in Stock" on the spreadsheet. But the bin is empty.

Now you are paying for overnight air freight while the machine sits idle.

On the flip side, Paula (the Finance Director) sees a warehouse full of dusty motors that haven't moved in 5 years. That is "Dead Capital."

To balance Availability (Mike's goal) with Cash Flow (Paula's goal), you need a CMMS with a robust Spare Parts Inventory Management module.

You need to move from "Guessing" to "Tracking."

Here are the 6 best CMMS tools for mastering your MRO (Maintenance, Repair, and Operations) inventory.

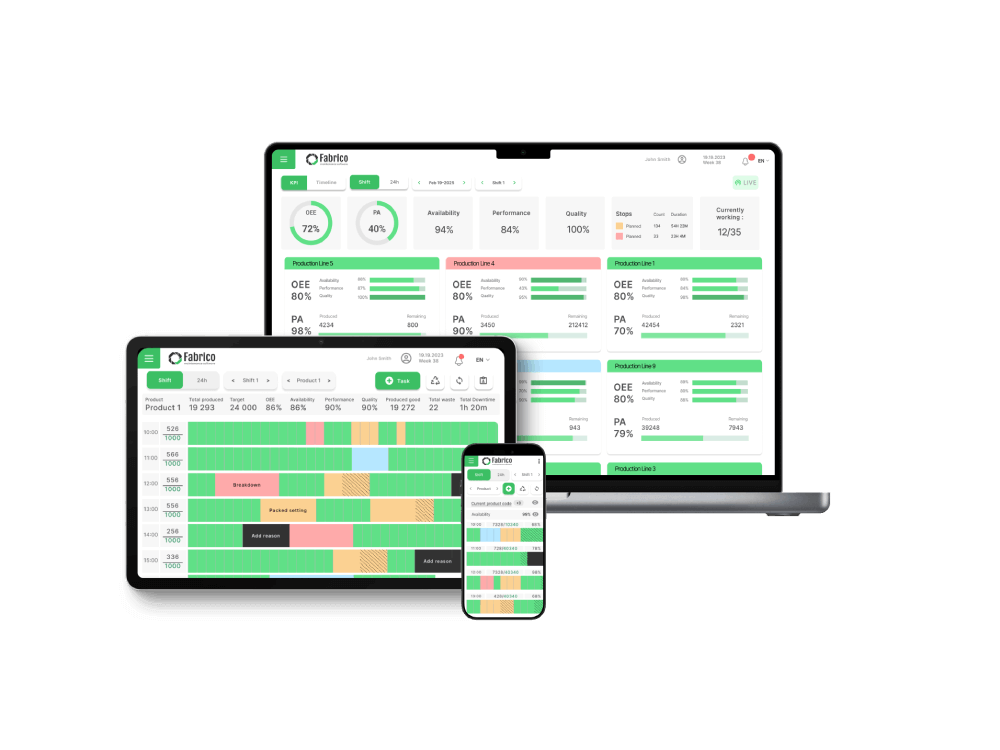

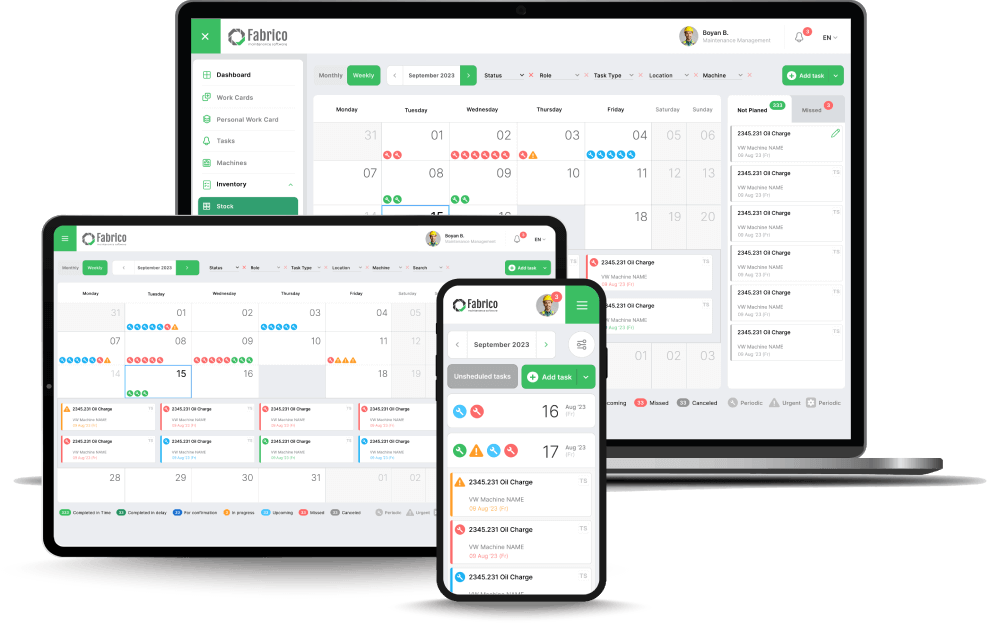

1. Fabrico (Best for Consumption Tracking & Vendor Mgmt)

Fabrico solves the biggest issue in spare parts: Data Discipline.

Parts usually go missing because a technician grabs one in a hurry and forgets to log it.

Fabrico integrates the inventory deduction directly into the Work Order workflow. A technician cannot close the repair without scanning the part they used.

This updates the inventory count instantly and logs the cost against the specific asset.

Key Inventory Features:

-

QR Code Checkout: Technicians scan the bin label to "check out" a part instantly. No typing part numbers.

-

Min/Max Automation: Set minimum stock levels for critical spares. When stock dips below the line, Fabrico flags it for reordering.

-

Vendor Management: Keeps your supplier details (Grainger, MSC, OEM) linked to the part. You know exactly who to call and what the last price was.

-

Asset-Part Linking: Shows you exactly which parts belong to which machine. If you are scrapping a machine, you know exactly which spare parts are now obsolete.

Best For: Manufacturing plants that need to stop stockouts and accurately track maintenance costs.

2. eMaint (Best for Purchasing Workflows)

eMaint (by Fluke) is a powerhouse for the Purchasing side of inventory.

For larger organizations where the Maintenance Manager can't just buy a part (they need a Purchase Order approved by Finance), eMaint excels.

It creates a seamless workflow: Technician Requests Part -> Manager Approves -> PO Generated -> Part Received -> Inventory Updated.

It is complex to set up, but for teams with strict financial controls, it provides the audit trail Finance demands.

Best For: Large organizations with strict PO (Purchase Order) approval processes.

3. Fiix (Best for Multi-Site Inventory)

Fiix (by Rockwell) is strong on Multi-Site management.

If you have three factories, Fiix allows you to see the inventory across all of them.

If Factory A is out of a motor, they can see that Factory B (10 miles away) has two in stock. This "Virtual Warehouse" capability prevents unnecessary purchasing.

It allows for internal transfers, which is a massive cost saver for enterprise groups.

Best For: Multi-site enterprises that want to share inventory.

4. Limble CMMS (Best for Simple Parts Tracking)

Limble applies its "Simplicity" philosophy to parts.

It doesn't have the complex PO workflows of eMaint, but it covers the basics perfectly.

It tracks: How many do I have? Where is it? When should I buy more?

Its strength is the visual notification system. It sends push notifications to the manager when a critical part hits the minimum threshold. It’s simple, effective, and stops the "out of stock" surprise.

Best For: Smaller teams who need to track parts without complex procurement logic.

5. PartsBox (Best for Electronics & BOMs)

PartsBox is a niche tool designed specifically for Electronics Manufacturing and engineering labs.

It excels at managing "BOMs" (Bill of Materials) for electronic components (resistors, capacitors, chips).

It handles "Attrition" well (e.g., losing small components during assembly).

While not a full CMMS (it doesn't manage work orders for heavy machinery well), for an electronics lab or assembly floor, it is superior to general tools.

Best For: Electronics manufacturers and R&D labs.

6. Sortly (Best for Visual Inventory Only)

Sortly is not a CMMS. It is a visual inventory app.

However, many small shops use it because it is incredibly easy.

You take a picture of the part, add tags, and you are done. It focuses entirely on "What is on the shelf."

The downside is that it is disconnected from your maintenance. It doesn't know why the part was used or which machine it went into. It tells you stock levels, but not asset history.

Best For: Very small shops that just need to organize a messy supply closet.

Comparison: The Supply Closet

Which tool organizes your shelf?

| Feature |

Fabrico |

eMaint |

Fiix |

Limble |

PartsBox |

Sortly |

| Primary Strength |

Usage Tracking |

Purchasing (PO) |

Multi-Site |

Simplicity |

Electronics |

Visuals |

| CMMS Native |

Yes (Unified) |

Yes |

Yes |

Yes |

No |

No |

| Workflow |

Scan-to-WO |

Req-to-PO |

Transfer |

Alert |

Build |

Scan |

| Min/Max |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

| Cost |

Subscription |

High |

High |

Medium |

Low |

Low |

Conclusion: Stop Buying, Start Managing

Inventory is cash sitting on a shelf.

If you have too much, you are wasting capital (Paula is mad).

If you have too little, you are risking downtime (Mike is mad).

If you just need to count boxes, Sortly works.

If you need to manage complex purchasing approvals, eMaint is best.

But if you want to link your inventory directly to your machine health—ensuring that every part purchased is a part actually needed for a specific repair—Fabrico offers the balanced solution that keeps both Finance and Maintenance happy.

Ready to organize your tool crib?

See how Fabrico tracks spare parts and prevents stockouts.

Book a Demo with Fabrico Today