Condition Monitoring (CM) is the heartbeat of a modern reliability strategy.

Instead of fixing a machine because "it's Monday" (Preventive), you fix it because "it's running hot" (Condition-Based).

But many manufacturers get stuck.

They buy vibration sensors or temperature probes, but the data sits in a siloed dashboard that nobody checks.

The machine fails while the sensor is screaming "RED ALERT" on a screen in an empty office.

You need Condition Monitoring Software that connects the Signal (Sensor) to the Action (Work Order).

Here are the 7 Best Condition Monitoring Tools for 2025.

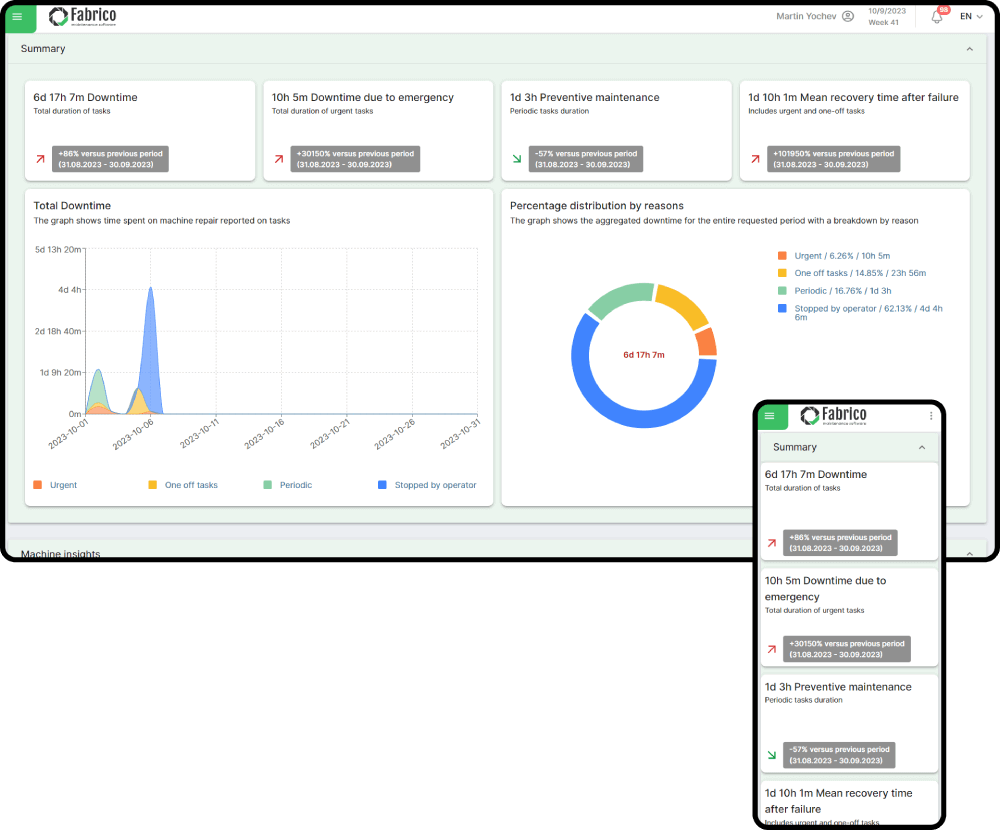

1. Fabrico: The "Action-Oriented" CM Platform

Best For: Manufacturers who want sensor thresholds to automatically trigger Maintenance Work Orders.

Fabrico solves the "Gap" between the sensor and the technician. We treat Condition Data as a trigger for execution.

Why Reliability Leaders Choose Fabrico:

-

Automated Workflows: You set the threshold (e.g., "Motor Temp > 75°C"). When the sensor hits that number, Fabrico instantly creates a High-Priority Work Order and pings the technician's phone. No human monitoring required.

-

Usage-Based Conditions: It's not just about sensors. Fabrico uses OEE Data (Cycle Counts/Runtime) as a condition. "Change oil after 500 hours" is monitored automatically via PLC integration.

-

Visual Health: The asset tree shows color-coded health status. You can see at a glance which production line is "Green" and which is "Yellow/Red."

-

Hardware Agnostic: Fabrico connects to your existing PLCs and third-party IoT sensors via API. You aren't locked into buying proprietary hardware.

The Verdict: If you want your machines to "call for help" and get an immediate response, Fabrico is the integrated choice.

2. eMaint (Fluke Reliability)

Best For: Fluke sensor integration.

eMaint is the software arm of the Fluke empire.

-

Pros: If you use Fluke’s handheld vibration testers or their wireless sensors, eMaint ingests that data natively. It is excellent for tracking the history of vibration readings on rotating assets.

-

Cons: The user interface is older. It can be difficult to integrate with non-Fluke hardware or complex PLC data without significant configuration.

-

The Niche: Vibration Analysis.

3. Aveva (Asset Performance)

Best For: Process industries (Oil & Gas, Chemical).

Aveva excels at monitoring continuous data streams in heavy industry.

-

Pros: Deep integration with SCADA and Historians (OSIsoft PI). It can monitor thousands of data points per second (Pressure, Flow, Temp) and detect complex anomalies.

-

Cons: It is expensive and heavy. It is designed for engineers in a control room, not necessarily for the mechanic on the shop floor.

-

The Niche: Process Control Monitoring.

4. Fiix (Rockwell Automation)

Best For: Rockwell hardware environments.

Fiix uses its connection to Rockwell to pull condition data from the factory floor.

-

Pros: Good connectivity with Allen-Bradley PLCs. The "Asset Risk Predictor" uses this data to highlight machines at risk.

-

Cons: Setting up the data mapping from the PLC to the CMMS can be technical. It often requires a dedicated controls engineer to configure.

-

The Niche: Automated Manufacturing.

5. Augury

Best For: AI-driven Machine Health.

Augury is a specialized tool for diagnosing mechanical health (Bearings/Motors).

-

Pros: It doesn't just show you a waveform; it tells you "Inner Race Bearing Defect." The AI diagnostics are superb for rotating equipment.

-

Cons: It is a "Doctor," not a "Hospital." It diagnoses the illness, but you still need a separate CMMS to manage the surgery (the repair).

-

The Niche: Diagnostics.

6. Samsara

Best For: Remote assets and simple monitoring.

Samsara is great for monitoring assets that aren't bolted to the factory floor (Generators, Compressors, Vehicles).

-

Pros: "Plug and Play" gateways. You can stick a sensor on a remote pump and see the data in the cloud in minutes.

-

Cons: It is less focused on the complex "Production" context (OEE) of a manufacturing line.

-

The Niche: Remote Monitoring.

7. Limble CMMS

Best For: Simple sensor thresholds.

Limble offers a straightforward way to connect IoT sensors to work orders.

-

Pros: Very easy to set up "If This, Then That" logic for sensors. Good for smaller teams starting their journey.

-

Cons: It lacks the deep analytical history and complex logic (combining multiple variables) that heavy industry often requires.

-

The Niche: Simple CBM.

Comparison Matrix: Monitoring vs. Managing

| Feature |

Fabrico |

eMaint |

Aveva |

Augury |

Samsara |

| Work Order Trigger |

✅ Native |

✅ Native |

⚠️ Complex |

❌ No |

⚠️ Basic |

| OEE Integration |

✅ Native |

❌ No |

✅ Native |

❌ No |

❌ No |

| Sensor Agnostic |

✅ Yes |

❌ Fluke |

✅ Yes |

❌ Proprietary |

❌ Proprietary |

| User Experience |

Modern |

Dated |

Complex |

Excellent |

Excellent |

| Cost |

Value |

High |

Premium |

Premium |

Mid |

Summary: Connect the Pulse to the Brain

Condition Monitoring is useless if the data dies in a dashboard.

-

Choose Aveva if you are monitoring a refinery.

-

Choose Augury if you need deep vibration diagnostics.

-

Choose Fabrico if you are a Manufacturer. If you want to take the pulse of your machines (Temperature, Cycles, Vibration) and use it to automatically drive your maintenance schedule and improve OEE, Fabrico is the unified solution.

Listen to your machines.

[Book a Demo with Fabrico] to see how we turn sensor data into maintenance action.