Brewing and Distilling is a romance of chemistry and a battle of logistics.

You spend weeks crafting the perfect liquid in the fermenters. But when it’s time to put that liquid into bottles or cans, the chaos begins.

Packaging lines in breweries are notorious for Micro-Stops. A labeler jam.

A foam-over at the filler. A crown cap that doesn't seat right.

In this industry, OEE (Overall Equipment Effectiveness) is the difference between a profitable craft brewery and a hobby.

Standard manufacturing tools often fail here because they don't understand the unique constraints of Liquid Filling, Excise Tax Compliance, and CIP Cycles.

Here are the 6 best OEE software tools specifically suited for Breweries and Distilleries.

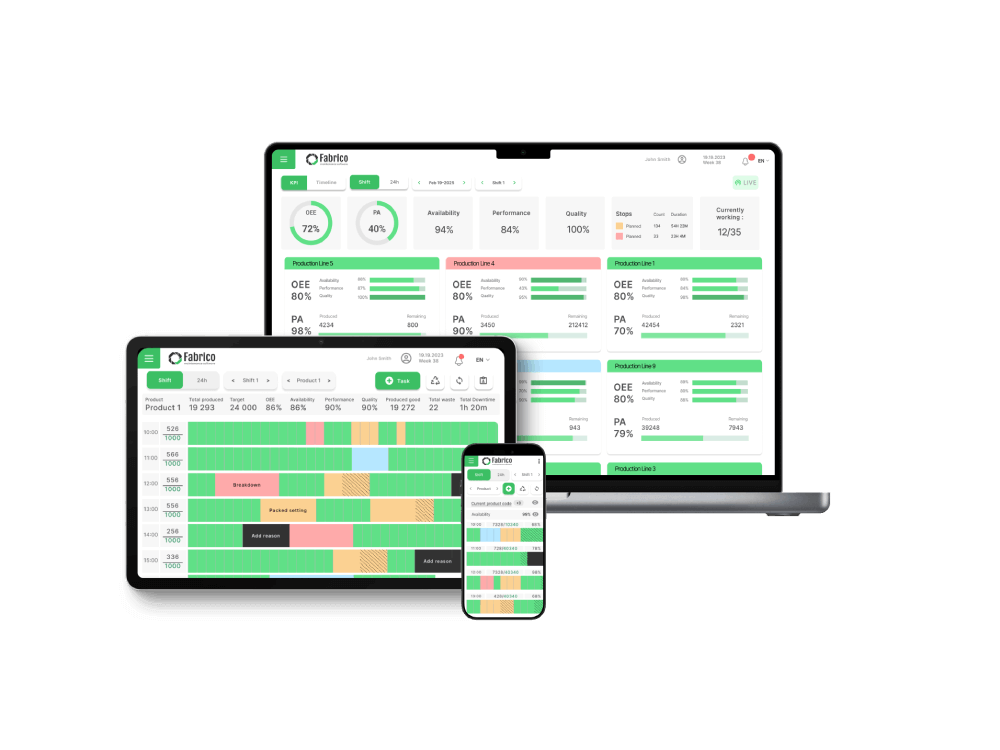

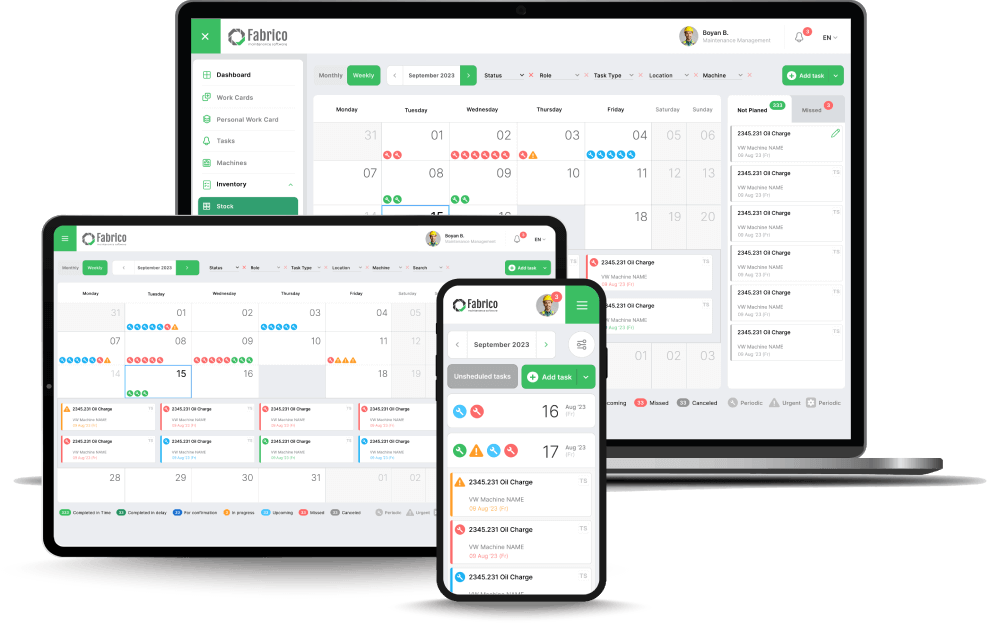

1. Fabrico (Best for Packaging Reliability & CIP)

Fabrico targets the number one cause of downtime in the brewery: Mechanical Failure on the Packaging Line.

Fillers, seamers, and labelers are complex, high-speed machines with thousands of moving parts.

If a seamer roller wears out, you start crushing cans.

Fabrico links OEE directly to Maintenance.

Key Features for Breweries:

-

Micro-Stop "Zoom-In": High-speed canning lines jam faster than the eye can see. Fabrico’s Computer Vision captures video of the jam, helping you tune the transfer arms perfectly.

-

CIP Cycle Optimization: Tracks the duration of Acid/Caustic cycles. If a 45-minute CIP routinely takes 60 minutes, Fabrico flags the deviation.

-

Maintenance Workflows: Automatically schedules lubrication for the filler carousel and seamer heads based on run-hours, preventing seizures.

-

Changeover Digital SOPs: Breweries constantly switch formats (12oz, 16oz, Kegs). Fabrico’s digital checklists ensure the line is set up correctly the first time to minimize beer loss.

Best For: Breweries focused on Packaging Line uptime and mechanical reliability.

2. OrchestratedBEER (Best for Brewery ERP)

OrchestratedBEER (OBeer) is the industry standard ERP.

It runs the business side: Inventory, Accounting, Sales, and Production Planning.

While not a real-time machine monitoring tool, its Production Module is essential for calculating the "Financial OEE."

It tracks the volume of liquid moved from tank to tank. It calculates Yield Loss (trub/yeast loss) with accounting precision.

Best For: Managing the financial and inventory side of the brewery (Grain to Glass).

3. OFS (Opportunity for Solutions) (Best for Line Performance)

OFS is a dedicated OEE software suite built specifically for the filling and packaging industry.

It creates a "Digital Twin" of the packaging line.

It excels at Operator Engagement. The interface is designed for the guy standing at the line. It asks simple questions: "Why did the line stop?"

It offers excellent reporting on Liquid Loss (Giveaway) and Material Waste (Cans/Labels).

Best For: High-speed bottling/canning lines needing detailed waste tracking.

4. LineView (Best for V-Curve & Accumulation)

LineView is for the high-volume breweries (the macro lagers).

When you run at 60,000 bottles per hour, line balancing is critical.

LineView uses True Causal Loss analysis. It analyzes the "V-Curve" of the line to see if the Accumulation Table is doing its job.

It tells you: "The filler stopped because the labeler downstream was blocked." This helps engineers resize conveyors and buffers to smooth the flow.

Best For: High-volume, complex packaging lines with flow balancing issues.

5. Vorne (Best for Craft Visuals)

Vorne is a favorite in the Craft Beer scene because it is simple and rugged.

The XL Scoreboard hangs above the canning line.

It shows the team: Target: 50 CPM. Actual: 42 CPM.

For a small team wearing rubber boots in a wet environment, this big red/green display is a powerful motivator. It doesn't require a server room or an IT guy.

Best For: Craft breweries needing a simple, visual pacing tool.

6. Ignition (by Inductive Automation) (Best for Custom SCADA)

Ignition is the "Swiss Army Knife" for brewery automation.

Many modern brewhouses run on Ignition SCADA.

Because it is modular, you can build your own OEE dashboards. You can track fermenter temperatures, glycol chiller performance, and canning line speed all on one screen.

It requires an integrator to set up, but it gives you infinite flexibility to control the process.

Best For: Breweries with a strong engineering team who want to customize their data.

Comparison: The Perfect Pour

Which tool fits your taproom?

| Feature |

Fabrico |

OBeer |

OFS |

LineView |

Vorne |

Ignition |

| Primary Strength |

Mechanical Reliability |

Financials (ERP) |

Operator Input |

Flow Analysis |

Visuals (Scoreboard) |

Process Control |

| OEE Focus |

Uptime & CIP |

Inventory Yield |

Waste & Speed |

Bottlenecks |

Speed Pacing |

Custom Data |

| Maintenance Link |

Native (CMMS) |

None |

Limited |

Limited |

None |

Custom Built |

| Changeovers |

Digital SOPs |

Scheduling |

Downtime Log |

Reporting |

Target Time |

Logic Control |

| Ideal For |

Ops & Maintenance |

Finance/Admin |

Packaging Mgr |

Engineer |

Floor Team |

Engineer |

Conclusion: Don't Spill the Profits

In brewing, you make money in the Brewhouse, but you lose money in Packaging.

If your struggle is Inventory and Taxes, OrchestratedBEER is the answer.

If your struggle is Line Balancing, LineView is the expert.

But if your struggle is that the Filler Keeps Jamming and the Seamer Needs Service, Fabrico provides the reliability tools to keep the cans moving and the beer flowing.

Ready to optimize your packaging line?

See how Fabrico handles changeovers and maintenance for breweries.

Book a Demo with Fabrico Today