Wood and Furniture manufacturing has transformed from a craft to a high-tech industry.

Modern factories use massive CNC nesting routers and automated edgebanders.

But the fundamental challenge remains: managing variation and maintaining reliability in a harsh environment.

OEE (Overall Equipment Effectiveness) in this sector is driven by:

-

Changeover Speed: Switching between different cabinet designs or custom orders.

-

Tool Management: Ensuring router bits and saw blades are sharp and clean.

-

Assembly Throughput: Optimizing the manual or semi-automated processes after machining.

Standard OEE tools often fail because they assume a clean, simple environment. You need software that understands Dust Collection, Tool Life Tracking, and the specific bottlenecks of Furniture Finishing and Assembly.

Here are the 6 best OEE software tools specifically suited for the Wood and Furniture industry.

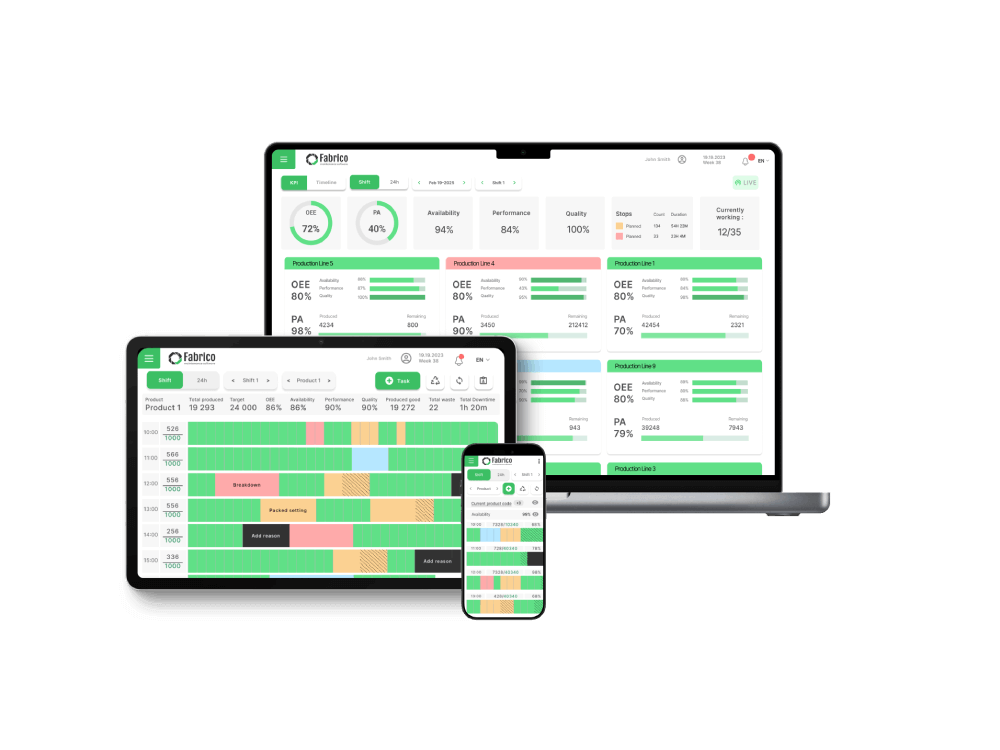

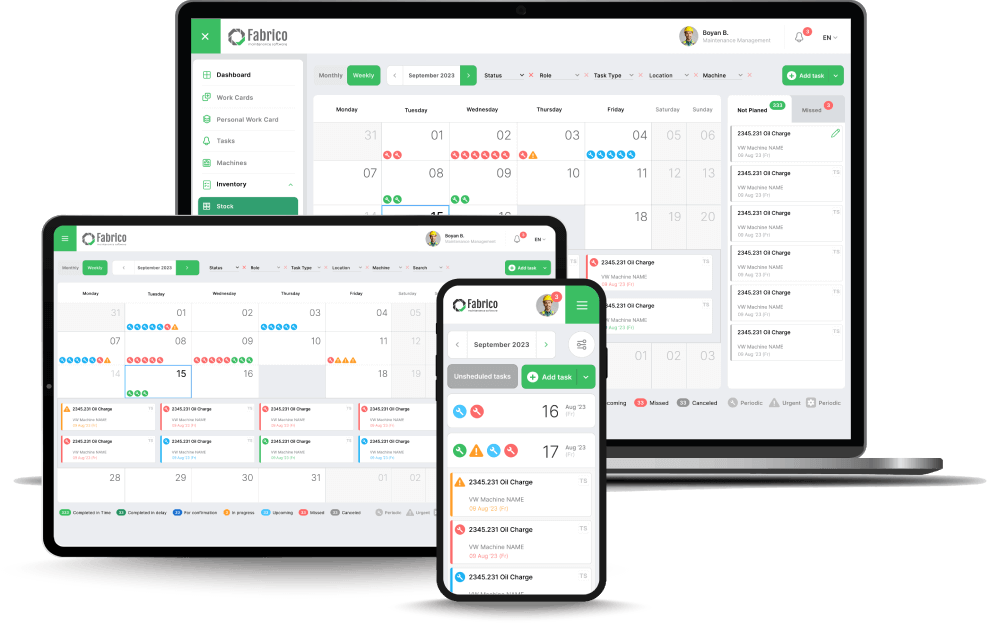

1. Fabrico (Best for Maintenance & Dust Management)

Fabrico focuses on the Reliability of woodworking equipment, directly addressing the industry's unique challenges.

Wood dust is the silent killer of CNC machines, sensors, and dust collection systems. Fabrico integrates maintenance workflows with the operational data to keep your plant running safely and efficiently.

Key Features for Woodworking:

-

Dust Collection Monitoring: Digitizes the critical inspections for dust collectors, cyclones, and filters. It tracks filter life and alerts maintenance when cleaning or replacement is needed, preventing fires and maintaining airflow for CNCs.

-

Tool Life Management: Tracks the usage (run hours/cycles) of router bits, saw blades, and shaper knives. It automatically schedules replacements or sharpening based on wear data, preventing premature quality defects (burning, tear-out).

-

Rugged Mobile App: Designed for the harsh shop floor environment. Technicians can perform inspections and log repairs on tablets, even with gloves on, capturing photos of tool wear or machine damage.

-

Assembly Tracking: Provides digital work instructions and time tracking for manual assembly stations, giving visibility into the efficiency of the finishing process.

Best For: Furniture plants focused on reducing downtime caused by dust, tool wear, and manual process bottlenecks.

2. Cyncly (2020 Insight) (Best for Design-to-Manufacturing Integration)

Cyncly (formerly 2020) is the dominant force in Cabinet and Furniture Design Software.

Their Insight MES connects directly to this design data. This means the CNC machine knows exactly what part to cut, what tool to use, and what edgebanding tape is required—all from the initial CAD file.

Key Features:

-

Automated Scheduling: Dynamically generates production schedules based on design orders.

-

Direct Machine Connectivity: Interfaces directly with Homag, Biesse, and Stiles CNC machines for seamless job loading.

-

Material Optimization: Integrates nesting software to minimize sheet waste.

Best For: Large cabinet manufacturers and OEM furniture makers needing a unified system from design to finished product.

3. tapio (Best for Homag Group Machinery)

tapio is the digital ecosystem built around the Homag Group of brands (Homag, Weeke, Stiles, Butfering).

If your plant floor is heavily invested in this machinery, tapio provides unparalleled insight.

Key Features:

-

Machine Connectivity: Plug-and-play integration with Homag CNCs, edgebanders, and panel saws.

-

Real-Time Status: Provides live updates on machine availability, operator, current job, and cycle time.

-

Remote Support: Enables remote diagnostics and support from the machine manufacturer.

Best For: Shops heavily utilizing Homag Group machinery.

4. productionCoach (RSA Solutions) (Best for Sorting & Assembly Workflow)

productionCoach (by RSA Solutions) focuses on optimizing the processes after machining.

Furniture manufacturing often involves hundreds or thousands of unique components that need to be sorted and assembled.

Key Features:

-

Part Tracking: Uses barcode scanning to manage the flow of machined parts to the assembly stations.

-

Assembly Guidance: Provides digital work instructions at the bench, ensuring correct assembly steps and reducing errors.

-

Labor Efficiency: Tracks operator performance on assembly tasks.

Best For: Custom cabinet shops and assembly operations where managing unique parts is the main challenge.

5. Global Shop Solutions (Best for Job Shop ERP & Costing)

Global Shop Solutions is a popular ERP system tailored for custom woodworking and millwork operations.

Its strength lies in Job Costing. It tracks the exact material, labor, and machine time for each unique order.

Key Features:

-

Shop Floor Data Collection: Allows operators to clock in/out of jobs and machines via tablets.

-

Real-Time Estimates: Compares actual production costs against the initial quote, highlighting profitability by job.

-

Inventory Management: Tracks lumber inventory and finished goods.

Best For: Custom Millwork and Job Shops needing precise financial control.

6. MachineMetrics (Best for CNC Optimization)

MachineMetrics provides real-time data acquisition and analytics, primarily for CNC machinery.

In a furniture plant with high-end CNC routers and edgebanders, it can monitor tool wear, spindle load, and cycle times.

Key Features:

-

CNC Performance: Tracks key metrics like Chip Load, Feed Rate, and Tool Life for routers and edgebanders.

-

Real-Time Alerts: Notifies supervisors of machine downtime or performance deviations.

-

Simple Interface: Easy for operators to use on the shop floor.

Best For: High-volume CNC operations focused on optimizing machining parameters.

Comparison: Machining vs. Finishing

Which tool fits your workflow?

| Feature |

Fabrico |

Cyncly |

tapio |

productionCoach |

Global Shop |

MachineMetrics |

| Primary Strength |

Reliability & Dust |

Design-to-Maching |

Homag Ecosystem |

Sorting & Assembly |

Job Costing (ERP) |

CNC Data |

| OEE Focus |

Uptime & Quality |

Flow & Setup |

Machine Status |

Process Flow |

Financial Margin |

Cycle Time |

| Maintenance Link |

Native (CMMS) |

Limited |

Native (Support) |

None |

Module |

Limited |

| Dust Mgmt |

Native (Checks) |

Limited |

Limited |

None |

Limited |

Limited |

| Ideal For |

Maintenance & Ops |

Cabinet Shops |

Homag Users |

Custom Assembly |

Job Shops |

High-Volume CNC |

Conclusion: Keep the Dust Down, Keep the Machines Running

In woodworking, you battle two forces: the design complexity and the physical environment.

If your main challenge is managing Custom Orders and integrating with design software, Cyncly is the standard.

If your bottleneck is Part Sorting or Assembly, productionCoach is the solution.

But if your struggle is the daily battle against Dust, Dull Tools, and Machine Breakdowns, Fabrico provides the essential maintenance workflows and rugged mobile tools to keep your woodworking operation running reliably.

Ready to keep the dust down?

See how Fabrico manages dust collection and CNC tool life for furniture plants.

Book a Demo with Fabrico Today