In 2025, walking into a factory should not feel like walking into 1990.

Yet, many plants are still run on paper.

-

Shift logs are written in notebooks.

-

Work orders are printed and handed out.

-

Safety permits are signed on clipboards and filed in cabinets.

Paper is a liability. It gets lost. It gets dirty. It is illegible. Most importantly, it is Dead Data.

You cannot search a stack of paper to find out which motor fails most often.

Paperless Manufacturing Software turns that dead data into live intelligence.

Here are the 7 Best Paperless Manufacturing Tools to digitize your operations in 2025.

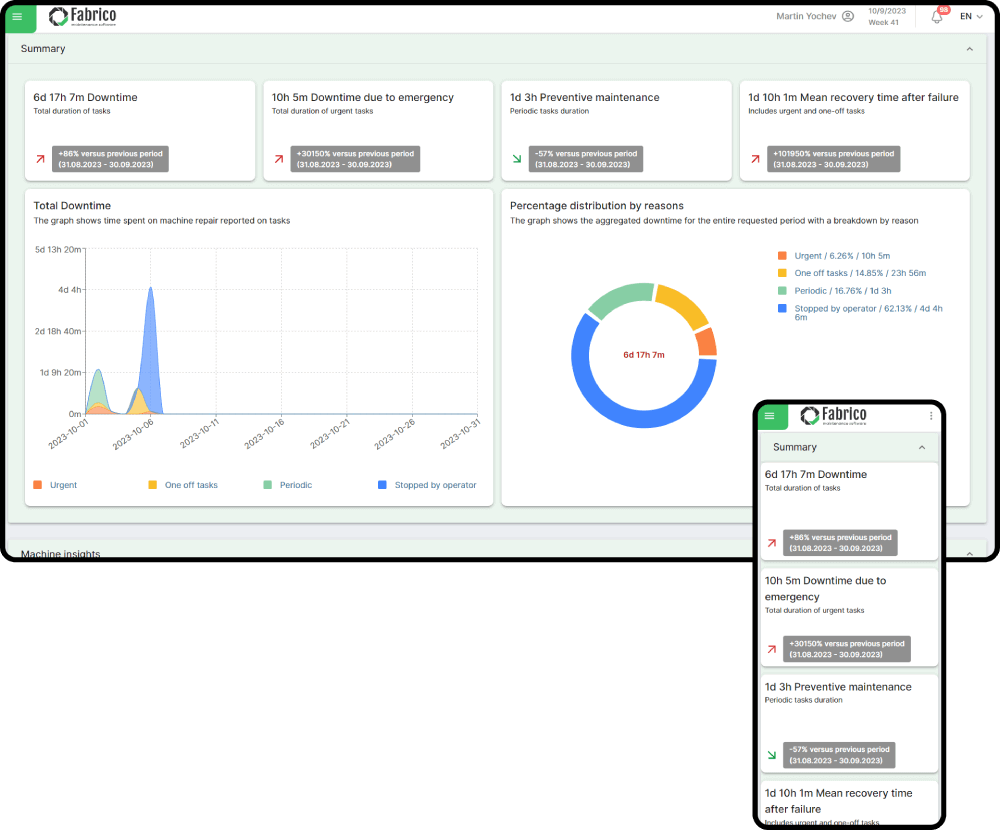

1. Fabrico: The "All-in-One" Factory OS

Best For: Manufacturers who want to digitize Maintenance, Production, and Quality in a single app.

Fabrico creates a "Paperless Ecosystem."

Instead of buying one app for safety forms and another for work orders, Fabrico handles the entire operational workflow.

Why Digital Leaders Choose Fabrico:

-

Digital Work Orders: Technicians receive jobs on their phones. They view manuals, upload photos, and close jobs digitally. No printing required.

-

Automated OEE: Instead of operators writing downtime codes on a tally sheet, Fabrico connects to the machine (PLC) to record stops automatically.

-

Smart Forms: Safety permits (LOTO) and Quality Checks are digital. You can force mandatory fields (e.g., "Must take photo of seal") to ensure compliance.

-

Searchable History: Every action is indexed. You can search "Conveyor 4" and see every repair, inspection, and operator note from the last 5 years instantly.

The Verdict: If you want to eliminate paper across the entire shop floor, Fabrico is the unified choice.

2. SafetyCulture (iAuditor)

Best For: Digitizing inspections and audits.

SafetyCulture is the world leader in digital forms. If your primary paper volume comes from safety audits and quality checklists, this is the standard.

-

Pros: The best form builder on the market. You can convert any paper checklist into a smart digital form in minutes.

-

Cons: It creates a data silo. The inspection data lives in SafetyCulture, but it doesn't natively connect to your maintenance work order backlog without custom integration.

-

The Niche: Inspections & Audits.

3. Parsable

Best For: Connected Worker & SOPs.

Parsable focuses on "Digital Work Instructions." It replaces the 3-ring binder of Standard Operating Procedures (SOPs).

-

Pros: Interactive instructions. Operators can watch videos, collaborate with experts, and track task duration.

-

Cons: It is heavy enterprise software. It focuses on the human process, but lacks the direct machine integration (OEE) of a platform like Fabrico.

-

The Niche: Complex manual processes.

4. MaintainX

Best For: Communication and simple workflows.

MaintainX replaces the "Paper Logbook" and the "Radio."

-

Pros: It looks like a chat app. Very high adoption rate because it feels familiar. Great for digitizing simple requests and safety forms.

-

Cons: It is less structured than heavy industrial tools. It is great for coordination, but lighter on deep reliability engineering data.

-

The Niche: Team collaboration.

5. Tulip

Best For: Custom shop floor apps.

Tulip allows you to build your own paperless apps.

-

Pros: You can build a specific app for "Station 1 Assembly" that connects to a smart torque wrench and a digital screen.

-

Cons: You have to build it. It requires engineering time to design and maintain the apps.

-

The Niche: DIY Engineering.

6. GoCanvas

Best For: Simple form data collection.

GoCanvas is a straightforward tool for replacing specific paper forms (Invoices, Estimates, Daily Reports) with mobile apps.

-

Pros: Very affordable and easy to set up for simple data entry tasks.

-

Cons: It is a "Form" tool, not a "Management" tool. It captures data but doesn't manage the asset lifecycle or production performance.

-

The Niche: Small business data entry.

7. Poka (IFS)

Best For: Training and knowledge sharing.

Poka replaces paper training manuals with video guides.

-

Pros: Excellent for capturing tribal knowledge. Operators can record videos of how they fixed a problem, creating a digital library.

-

Cons: It is a knowledge base, not an execution engine. It doesn't manage the spare parts inventory or the automated maintenance triggers.

-

The Niche: Training & Knowledge.

Comparison Matrix: Digital vs. Paper

| Feature |

Fabrico |

SafetyCulture |

Parsable |

MaintainX |

Tulip |

| Maintenance |

✅ Native |

⚠️ Basic |

⚠️ Basic |

✅ Native |

⚠️ DIY |

| OEE / Production |

✅ Native |

❌ No |

❌ No |

❌ No |

✅ DIY |

| Digital Forms |

✅ Integrated |

✅ Best-in-Class |

✅ Advanced |

✅ Good |

✅ Custom |

| User Experience |

Modern |

Excellent |

Enterprise |

Excellent |

Modern |

| Setup Speed |

Weeks |

Days |

Months |

Days |

Months |

Summary: Go Paperless to Go Faster

Going paperless isn't just about saving trees. It's about Speed.

Digital data moves at the speed of light. Paper moves at the speed of a walking person.

-

Choose SafetyCulture if you just need better audits.

-

Choose MaintainX if you just need better communication.

-

Choose Fabrico if you want a Digital Factory. If you want to digitize the entire lifecycle of a problem—from the machine fault (OEE), to the work request, to the safety permit, to the repair—Fabrico is the integrated solution.

Recycle the clipboard.

[Book a Demo with Fabrico] to see how we turn your paper processes into digital intelligence.