The manufacturing world is changing fast.

Factories are becoming smarter, faster, and more connected.

Industry 5.0 is emerging as the next step in this evolution.

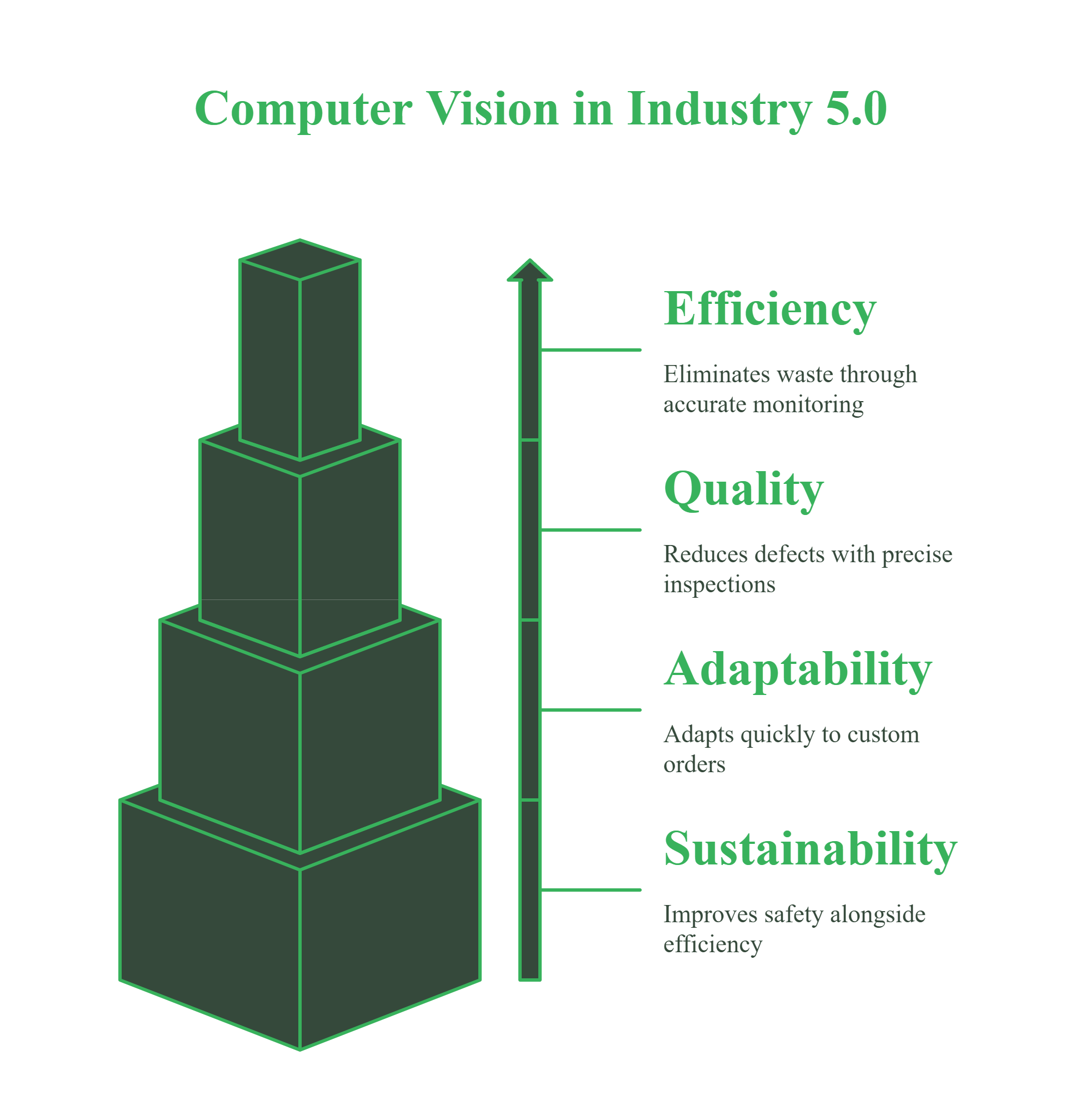

It focuses on combining human creativity with machine intelligence.

Manufacturers are no longer aiming just for automation.

They want collaboration, efficiency, and sustainability.

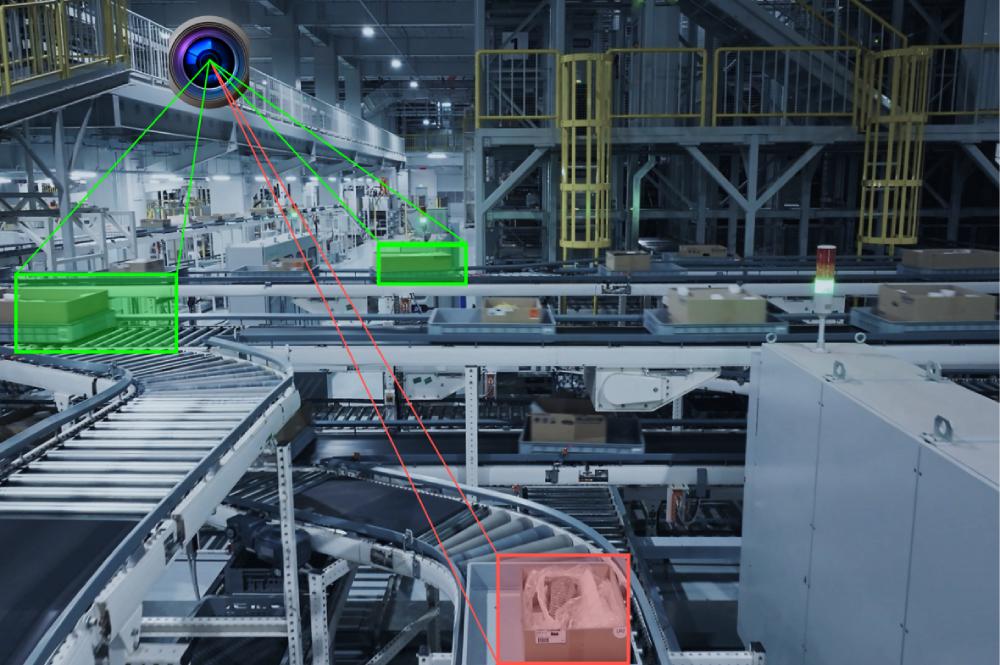

One technology at the heart of this shift is computer vision in manufacturing.

It gives machines the ability to see, measure, and act.

Combined with tools like Fabrico’s OEE, it brings real, actionable insights to the production floor.