In a fully automated factory, OEE (Overall Equipment Effectiveness) is easy. The PLC tells you when the machine runs and when it stops.

But what if your "Machine" is a team of 10 people assembling electronics, packing gift sets, or welding frames?

For Continuous Improvement Leads and VP of Operations, manual and hybrid lines are the hardest areas to optimize.

You know you have inefficiencies. You see people standing around. You see variability between Shift A and Shift B. But you have no data to prove why.

Standard OEE tools fail here because there is no PLC to plug into. You cannot install a sensor on a person.

To improve manual production, you need a different approach: Digitizing the Human Process.

The Challenge: Why Manual OEE is Different

On an automated line, "Performance Loss" means the motor slowed down.

On a manual line, "Performance Loss" means:

-

Micro-Waits: The operator is waiting 5 seconds for the conveyor to bring the part.

-

Motion Waste: The operator has to reach too far for the screwdriver.

-

Documentation: The operator stops working to write on a clipboard.

If you don't measure these, you can't fix them. But asking operators to "write down every time you stop" is a recipe for bad data and angry workers.

Strategy 1: The "Digital Andon" Tablet (Operator Feedback)

The first step is to give the operator a voice.

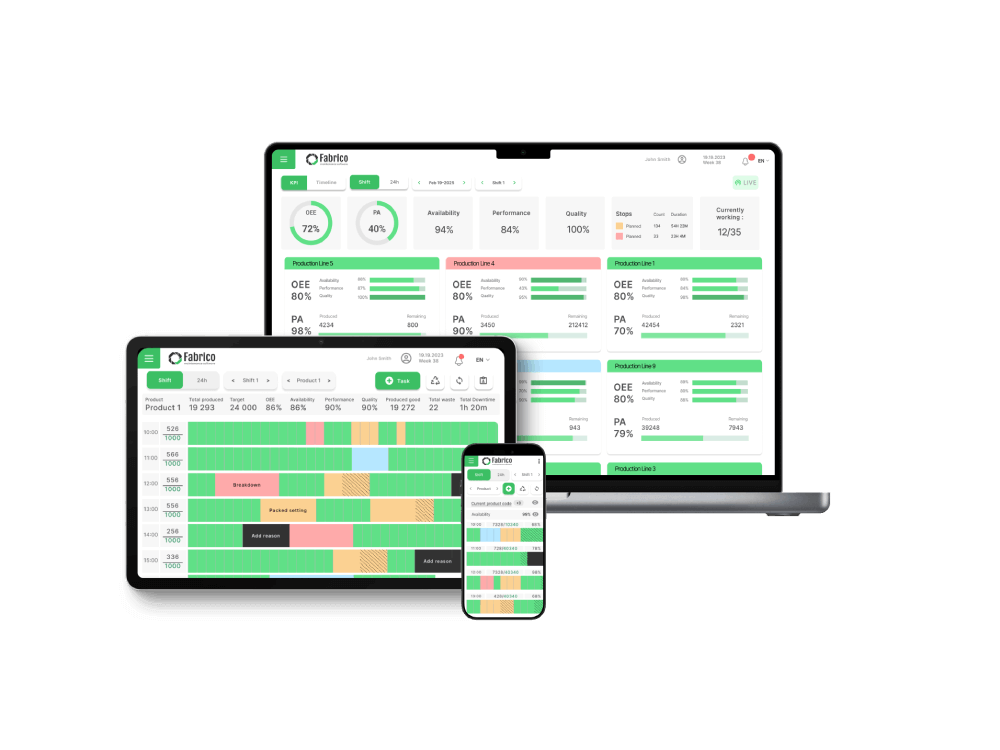

Replace the paper tally sheet with a Fabrico Tablet at the station.

-

Good Count: The operator taps "Finish" (or uses a foot pedal/button) to log a unit. This calculates real-time Cycle Time.

-

Downtime: If they stop, they tap "Waiting for Material."

The Result: You instantly see the "Heartbeat" of the manual line. You can spot that Station 3 is the bottleneck because they are consistently 10 seconds slower than Station 2.

Strategy 2: Computer Vision (The Passive Observer)

Asking operators to log data adds friction. Computer Vision removes it.

Fabrico uses cameras to "watch" the manual station. The AI is trained to recognize the work cycle.

If the operator walks away or the line stops moving, Fabrico logs "Downtime."

This provides 100% accurate OEE without the operator ever touching a screen or wearing a sensor. It turns physical motion into digital data.

Strategy 3: Digital Work Instructions (Standardizing the Human)

Variability is the enemy of OEE. If Tom assembles the kit in 2 minutes and Jerry takes 3 minutes, your planning is broken.

Fabrico delivers Digital Work Instructions (videos/images) to the tablet.

It ensures that both Tom and Jerry follow the exact same sequence. This reduces Quality Losses (rework) and stabilizes the Performance Rate.

Summary: Lighting Up the Dark Factory

You cannot optimize what you cannot see.

If your manual lines are a "Black Box," you are leaving capacity on the table.

By using Fabrico to digitize the manual workflow—either through tablets or computer vision—you gain the same visibility into your human workforce that you have into your CNC machines.

You move from "anecdotes" ("I think they are waiting for parts") to evidence ("They waited 42 minutes for parts today").

Ready to see your manual efficiency?

See how Fabrico’s Computer Vision turns manual motion into OEE data.

Book a Demo with Fabrico Today