1. From static KPI to system indicator

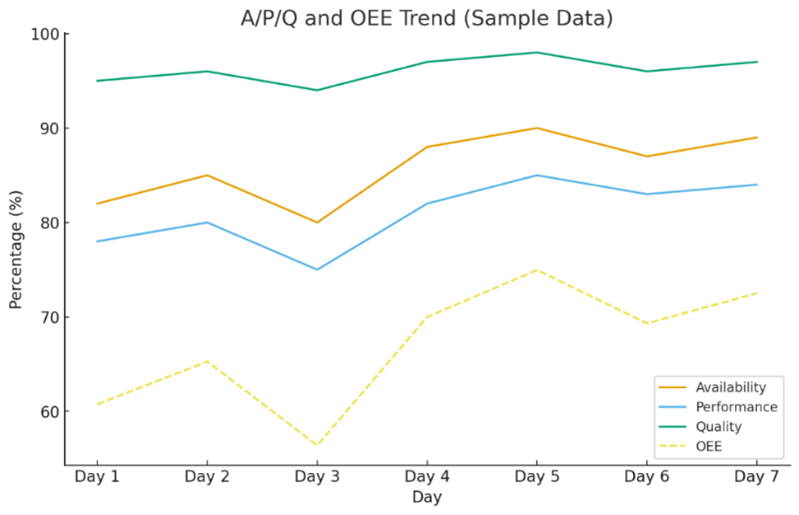

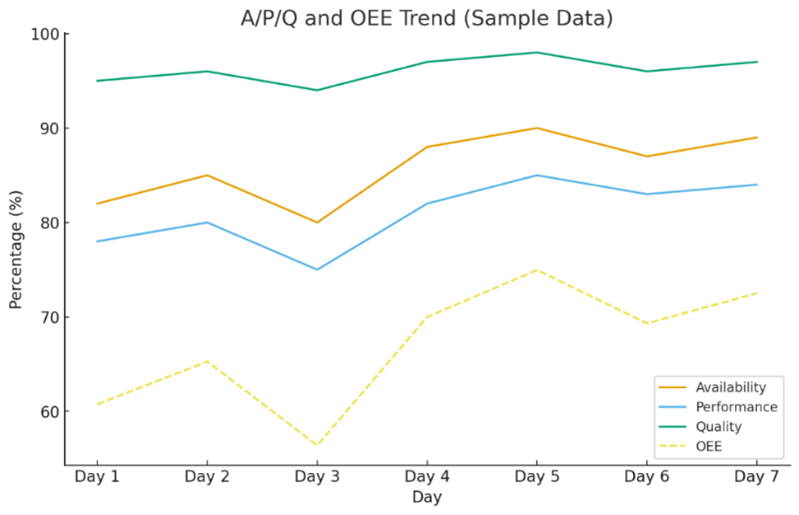

Across industries, OEE is increasingly treated as a system performance indicator, rather than a scorecard number. Instead of chasing short-term gains, leading plants focus on how OEE behaves over time: its variation, sensitivity to change, and response to improvement actions.

2. Real-time visibility versus retrospective reporting

Manual, end-of-shift OEE reporting is giving way to real-time visibility. Manufacturers are investing in connected equipment, sensors, and digital platforms that allow teams to see performance deviations as they happen, enabling corrective action during the shift rather than after the fact.

3. Micro-losses as the new improvement domain

As major downtime is reduced, many manufacturers find that the largest remaining OEE gaps come from micro-losses: small stops, reduced speeds, and short quality interruptions. These losses are frequent, cumulative, and often invisible without high-resolution data.

4. Adoption across multiple industries

While OEE originated in discrete manufacturing, it is now widely used in food and beverage, pharmaceuticals, chemicals, automotive, electronics, and packaging. Each sector applies OEE differently, but the underlying goal is the same: understanding how equipment behavior affects overall flow and output.

5. A common language across functions

In high-performing organizations, OEE is no longer owned by maintenance alone. Instead, it is used as a shared performance language across operations, continuous improvement teams, production planning, and leadership, thus aligning daily decisions around the same operational reality.