The method you use to collect OEE data directly determines the quality of your decisions. Let's break down the common approaches.

Method 1: Manual Collection (The Clipboard & Paper Log)

How it works: An operator, Tom, keeps a log sheet at his station. He manually notes production counts, downtime events, and reject reasons throughout his shift.

The Painful Reality: This method is slow, prone to errors, and always out of date. It’s an extra burden on the frontline team and delivers lagging, unreliable data that forces managers like Mike to make decisions based on old news.

Method 2: Semi-Digital Collection (Spreadsheets & Excel)

How it works: A shared computer terminal is placed on the shop floor. Operators enter their production data directly into a spreadsheet at the end of their shift or during a lull.

The Marginal Improvement: While the data is now digital, it's still not real-time. This method is plagued by input errors, version control chaos, and a complete lack of integration into any maintenance workflow. It's a digital version of a broken process.

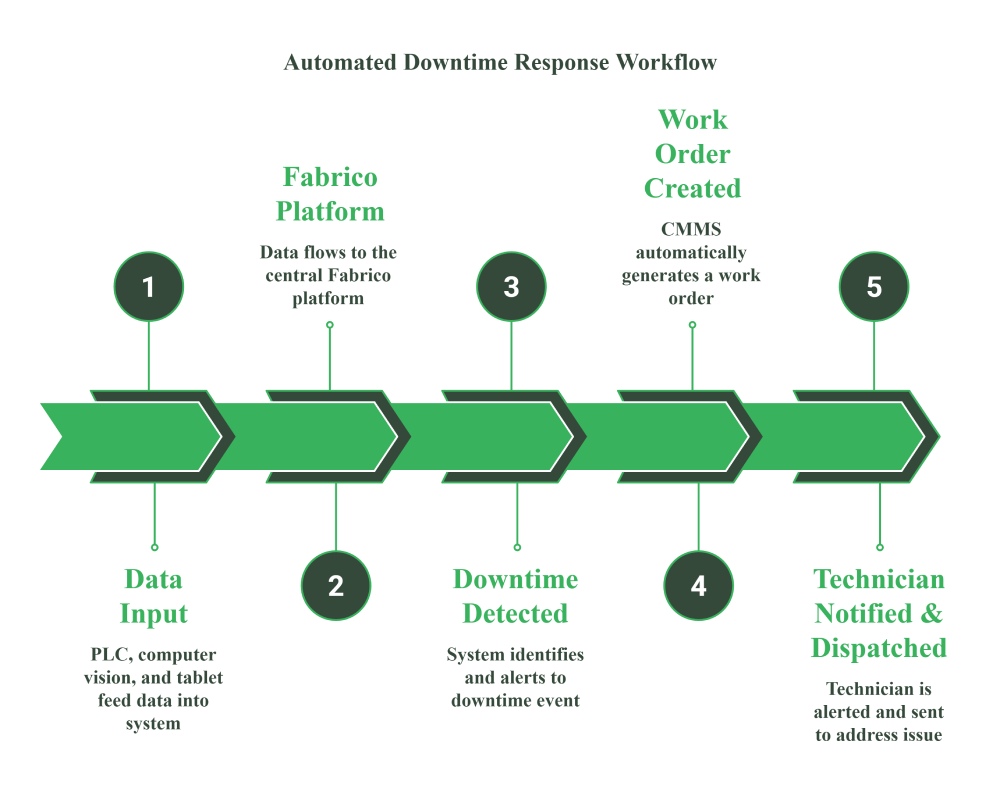

Method 3: Automated Collection (PLC & Sensor Integration)

How it works: A direct digital connection is made to a machine's controller (PLC) or to attached sensors. This allows the system to automatically log cycles, machine status (running/stopped), and fault codes.

The Benefits: This is the gold standard for accuracy and timeliness. It provides a stream of real-time, objective data with no extra work required from the operator.

The Limitation: This is great for your new, high-tech equipment. But what about that 20-year-old mechanical press or the offline assembly station that doesn't have a modern PLC?

Method 4: Advanced Automation (Computer Vision)

How it works: Think of a smart camera pointed at your machine. It can read an analog pressure gauge, watch a status light turn from green to red, or count finished goods moving down a conveyor belt.

The Game-Changing Benefit: Computer Vision allows you to get all the benefits of automation on your older, "un-connectable" legacy equipment. It’s like retrofitting your entire factory for the digital age, without the complex and costly rewiring.

The Fabrico Advantage: At Fabrico, we have integrated Computer Vision as a core data collection method. This ensures that every single asset in your plant, new or old, can become a source of real-time, actionable data.

Take a live tour with a product expert