Key Takeaways

-

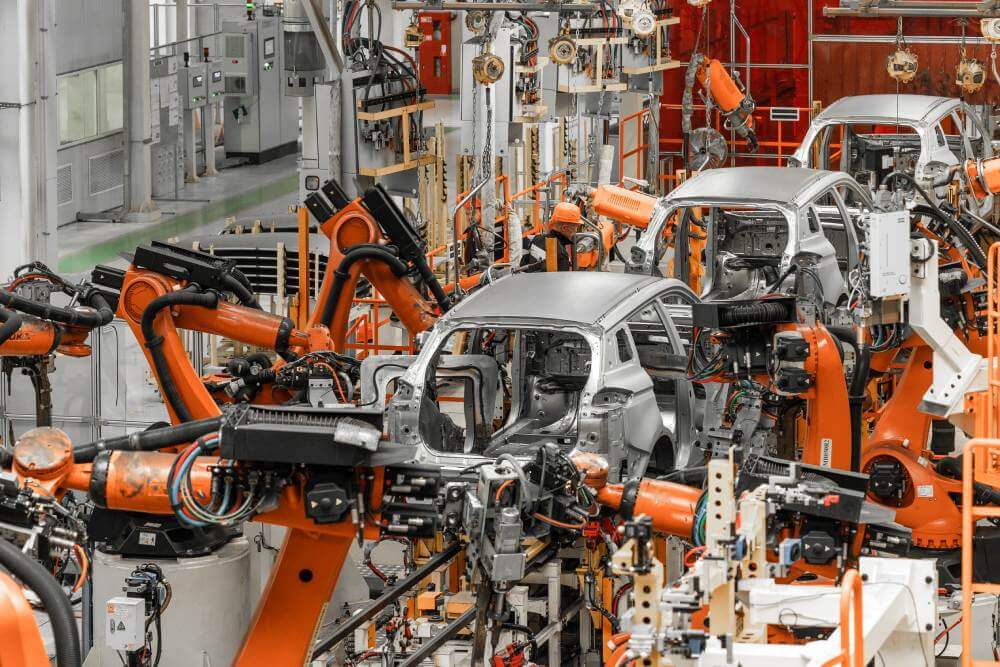

In the high-stakes automotive industry, OEE is the essential KPI for protecting your Just-in-Time (JIT) production schedule and driving Lean manufacturing principles.

-

The extreme cost of downtime (often exceeding $20,000/minute) means that a rapid, systematic response to any stop is not a goal, but a requirement for survival.

-

A true automotive solution connects a real-time OEE diagnosis (the alert) to an instant CMMS cure (the maintenance response), closing the gap between problem and solution in seconds.