What is a good OEE improvement strategy?

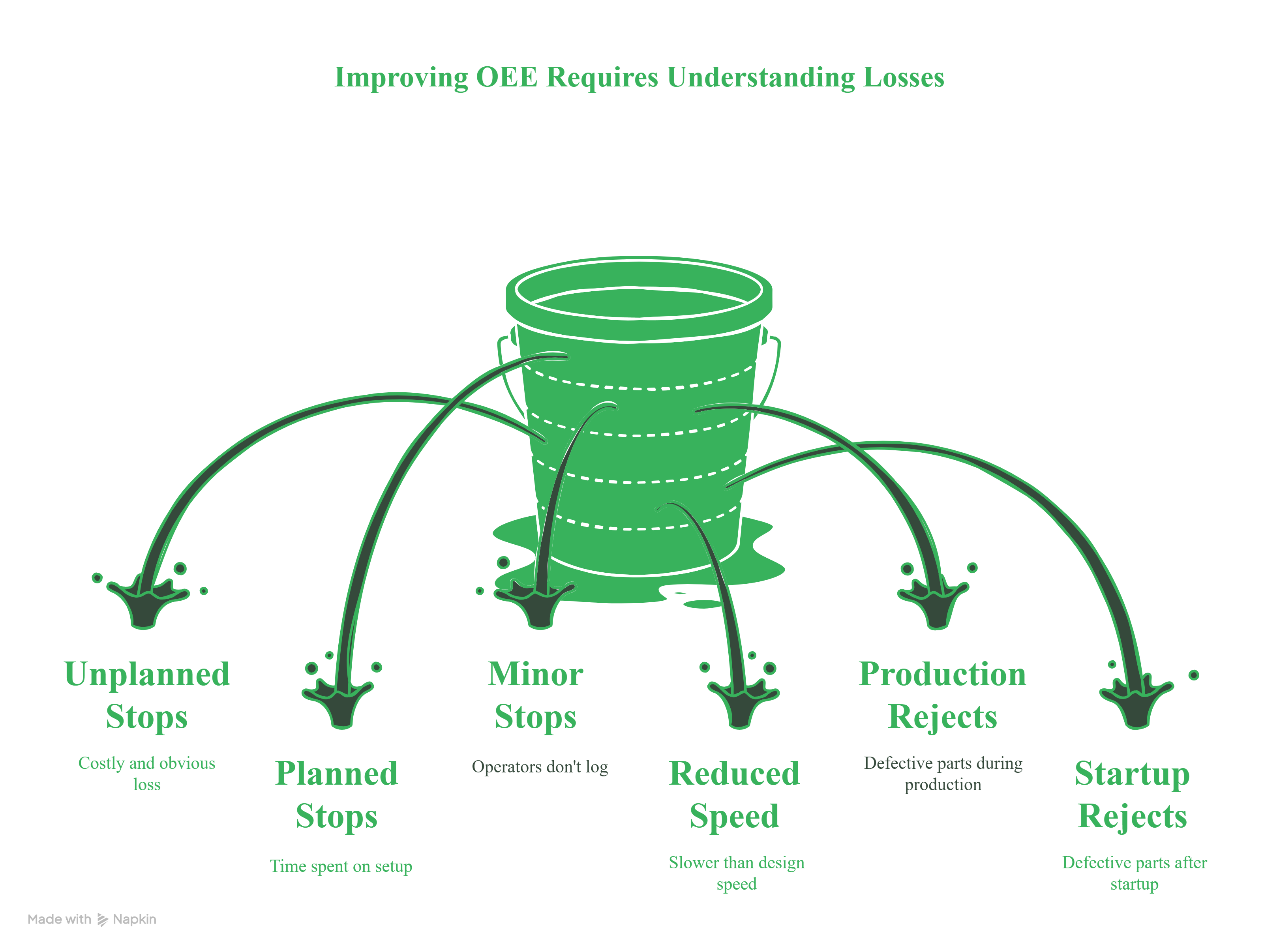

A good strategy is a holistic one that combines technology, process, and people. It starts with accurate, automated data collection (OEE monitoring), identifies the biggest sources of loss (bottlenecks, breakdowns), and uses a powerful tool like a CMMS to execute proactive maintenance and standardize work.

How do you increase availability in OEE?

The primary way to increase availability is by reducing unplanned downtime. This is achieved by shifting from a reactive ("firefighting") maintenance culture to a proactive one focused on preventive and predictive maintenance, all managed and tracked within a modern CMMS.

What are the three main components of an OEE improvement plan?

The three core components are:

1. Accurate Measurement: An automated system to track OEE and the Six Big Losses in real-time.

2. Systematic Analysis: A process for identifying the biggest constraints and finding the root cause of recurring problems.

3. Actionable Execution: A user-friendly tool (like a CMMS) that enables the maintenance team to execute proactive work, operators to report issues, and managers to track progress.

How can a CMMS help improve OEE?

A CMMS is the action-arm of an OEE strategy. While OEE software identifies problems like machine breakdowns (low availability), a CMMS is the system used to schedule preventive maintenance, manage work orders, track spare parts, and store critical maintenance history, all of which are essential to preventing those breakdowns from happening in the first place.