Key Takeaways

-

OEE Quality measures the percentage of good parts produced out of the total parts started, also known as First Pass Yield. The world-class benchmark is 99.9%.

-

The formula is a simple ratio: Quality = Good Count / Total Count.

-

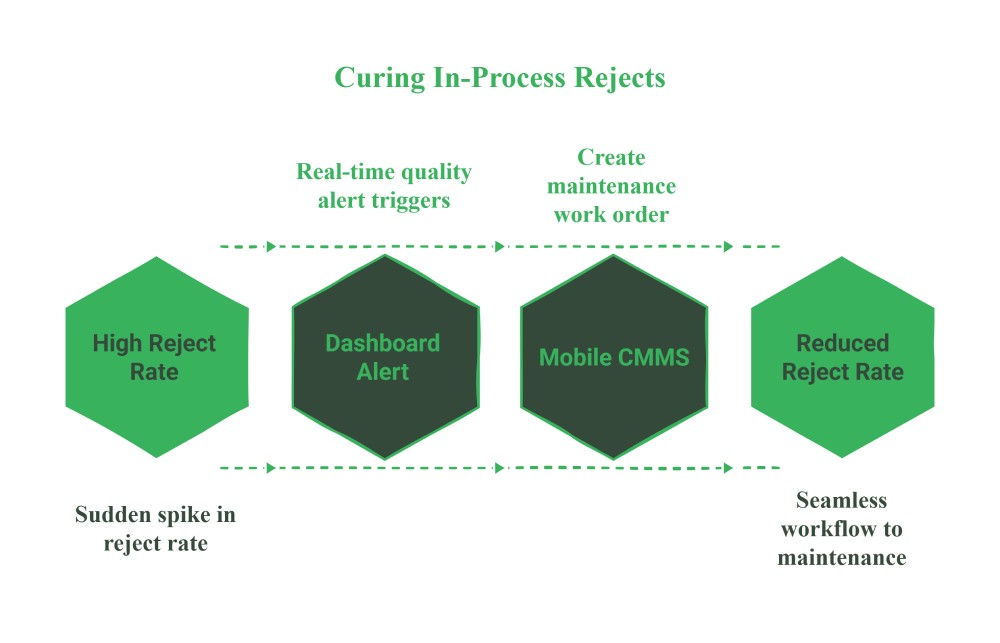

There are two types of quality loss: In-Process Rejects (often a machine health issue) and Startup Rejects (often a process or setup issue).

-

A true solution doesn't just track these losses; it uses an integrated CMMS to cure them by triggering maintenance actions and standardizing setup procedures.