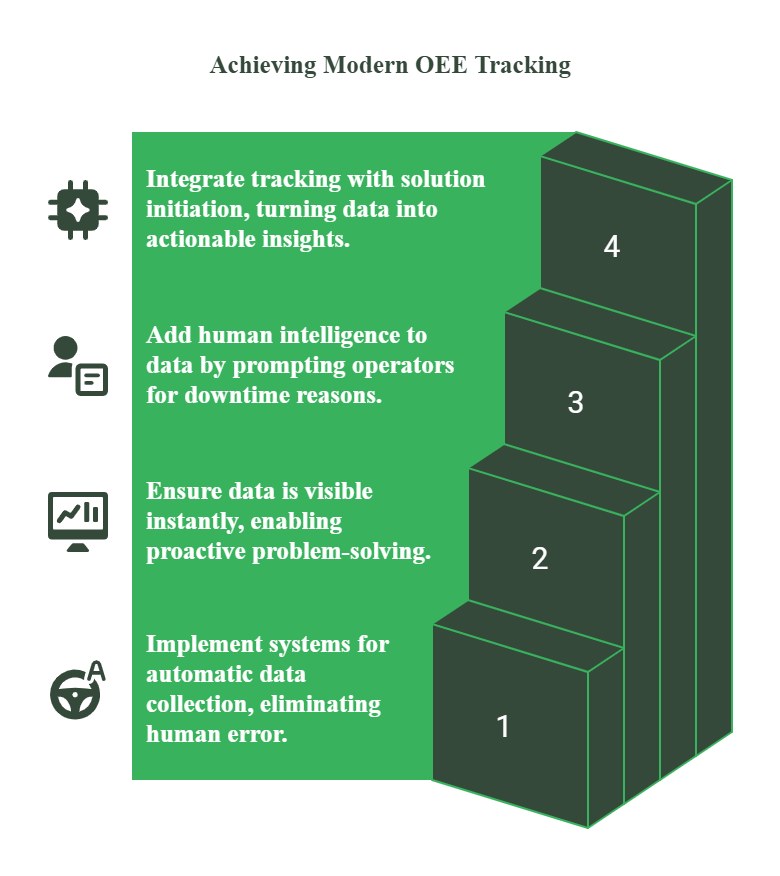

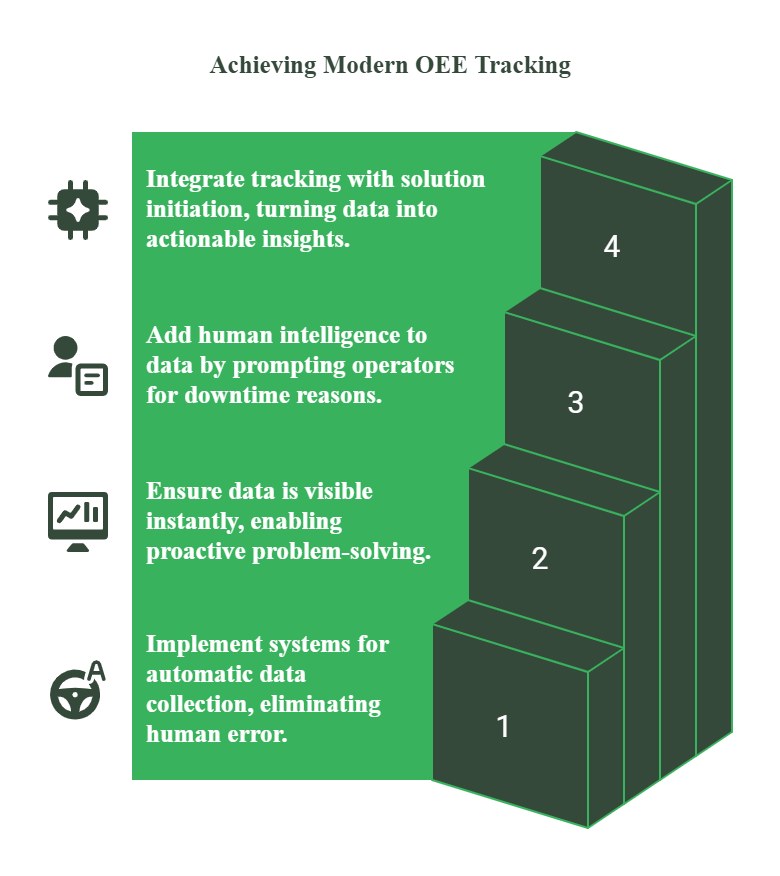

The goal isn't to get better at manual tracking. The goal is to replace a broken process with a modern, automated system. A modern system is built on four powerful pillars.

Pillar 1: Tracking is Automated

The New Way: Modern systems track production automatically. They use direct connections to a machine's controller (PLC) or advanced methods like computer vision to get real-time, 100% accurate data on machine status, cycle counts, and speed.

The Impact: This completely eliminates human error from the data collection process. It frees your operators from the burden of paperwork and ensures your decisions are based on fact, not fiction.

Pillar 2: Tracking is Real-Time

The New Way: The data isn't entered at the end of the shift. It's visible on a live dashboard the second it happens, accessible to everyone from the operator to the plant manager.

The Impact: This moves your team from reactive problem-solving to proactive intervention. You can see a machine running slower than spec right now and fix it before it ruins the entire shift's performance.

Pillar 3: Tracking is Enriched with Context

The New Way: While the what (the stop) is automated, the why still requires human intelligence. When a machine stops, a modern system prompts the operator on a simple, nearby tablet to select a downtime reason from a pre-defined, customized list.

The Impact: This simple, one-tap process is fast for the operator and provides structured, consistent data for root cause analysis. It's the end of vague, illegible notes on a paper log.

Pillar 4: Tracking is Connected to Action (The Ultimate Goal)

The New Way: This is the most critical pillar that separates a simple tool from a true solution. A modern system doesn't just track the problem; it starts the solution.

The Impact (The Fabrico Cure): The OEE tracking system is natively integrated with a CMMS. When a downtime event is tracked and the operator categorizes it as "Mechanical Failure," that's not the end of the process.

It's the beginning. It instantly triggers a work order in the CMMS that is sent to the maintenance team's mobile devices, closing the loop between the tracking system and the action system in seconds.

Take a live tour with a product expert