Availability losses are periods when the plant was scheduled to be running, but it wasn't.

Loss 1: Unplanned Stops (Equipment Failure)

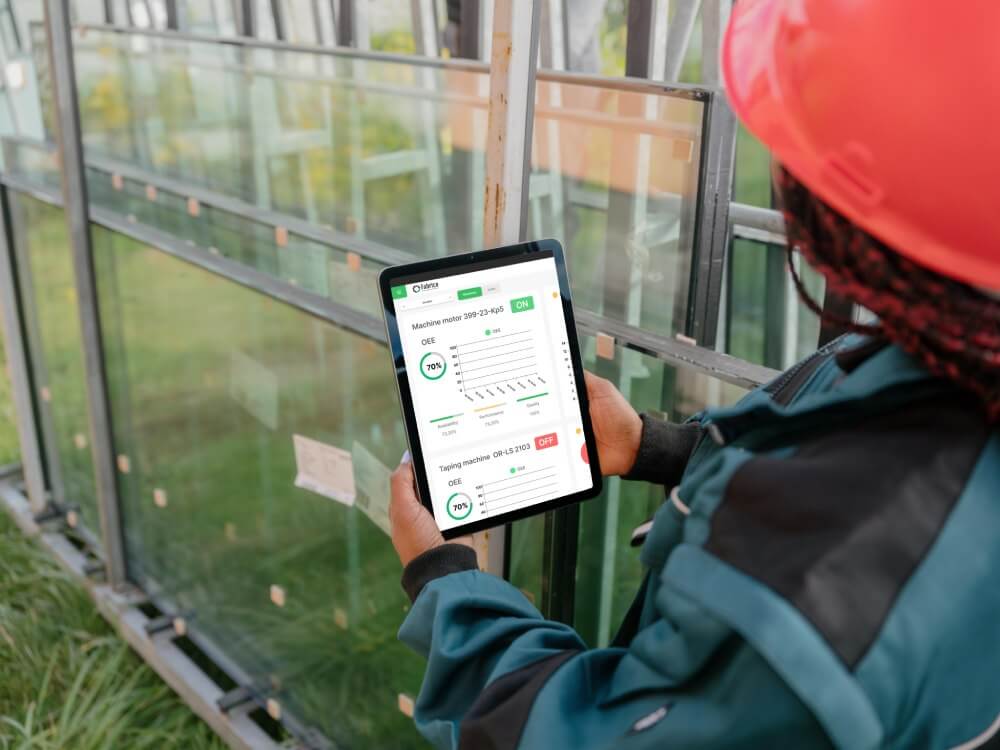

The Diagnosis: This is the most obvious and painful loss. A machine breaks down, a tool fails, a conveyor jams. Production comes to a halt unexpectedly. Real-time OEE software instantly alerts you the second it happens and tracks every single minute of lost production time.

The Cure: This is fundamentally a maintenance failure, and the cure lies in a modern CMMS. When Fabrico's OEE module detects an unplanned stop, it can automatically trigger a high-priority work order in the CMMS.

This closes the loop from the problem to the solution in seconds, not hours. Over time, this data helps you track MTTR and MTBF, allowing you to build a smarter preventive maintenance strategy that stops these failures from happening in the first place.

Loss 2: Planned Stops (Setup & Adjustments)

The Diagnosis: This loss occurs during the necessary planned stops for changeovers, tooling adjustments, material changes, or major inspections. OEE software precisely measures this time, often revealing that these "planned" events are taking much longer than people think.

The Cure: A CMMS streamlines and standardizes these planned stops. You can attach digital checklists, standard operating procedures (SOPs), and setup instructions directly to the changeover work order.

This ensures the process is done consistently and correctly every single time. By tracking this data, you can identify opportunities for SMED (Single-Minute Exchange of Die) projects to systematically shorten your changeover times.