Once you can see these hidden losses, how do you cure them? The most effective approach is to treat your Performance data as a predictive early warning system for your maintenance team.

Step 1: Make the Invisible, Visible (The Diagnosis)

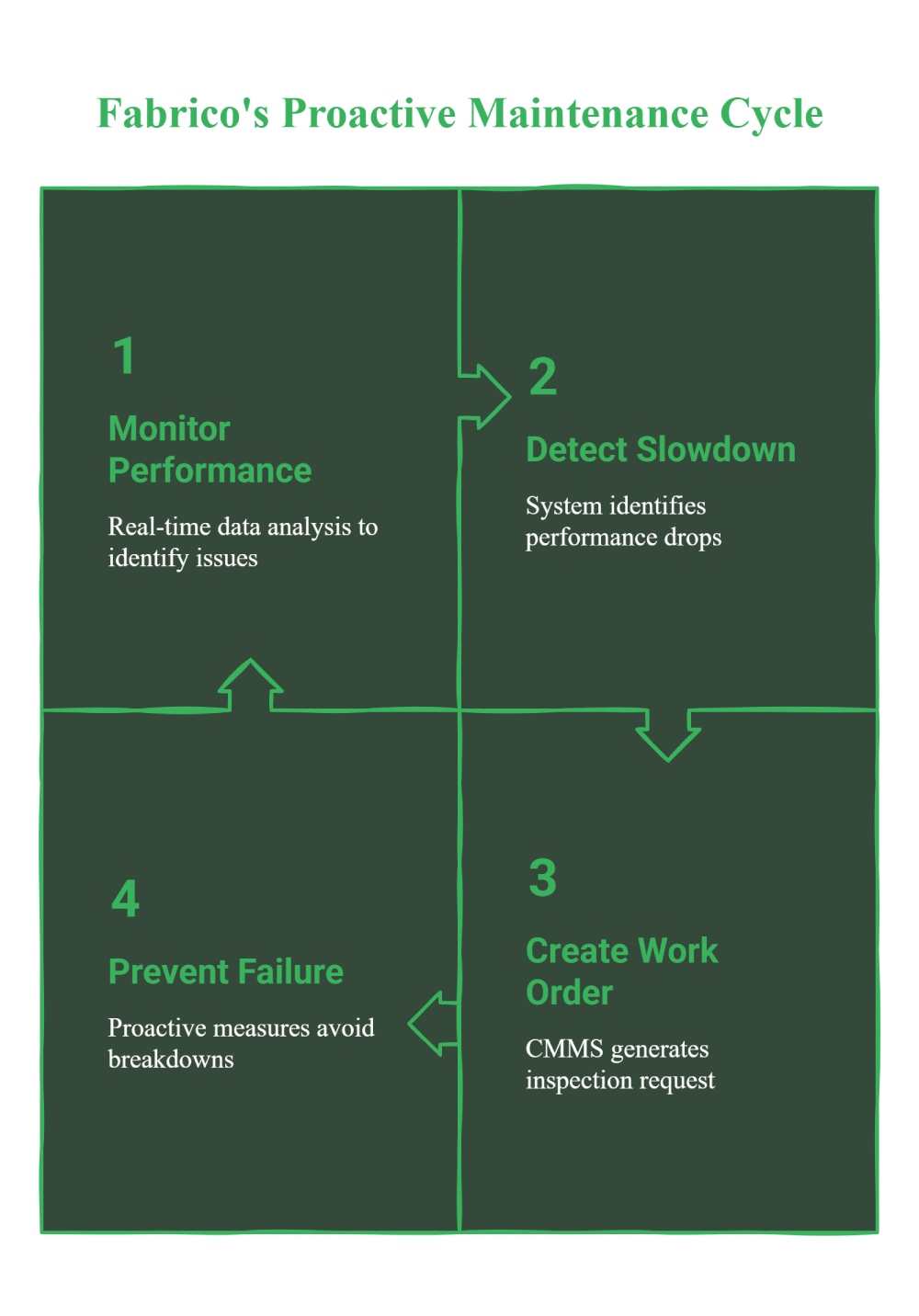

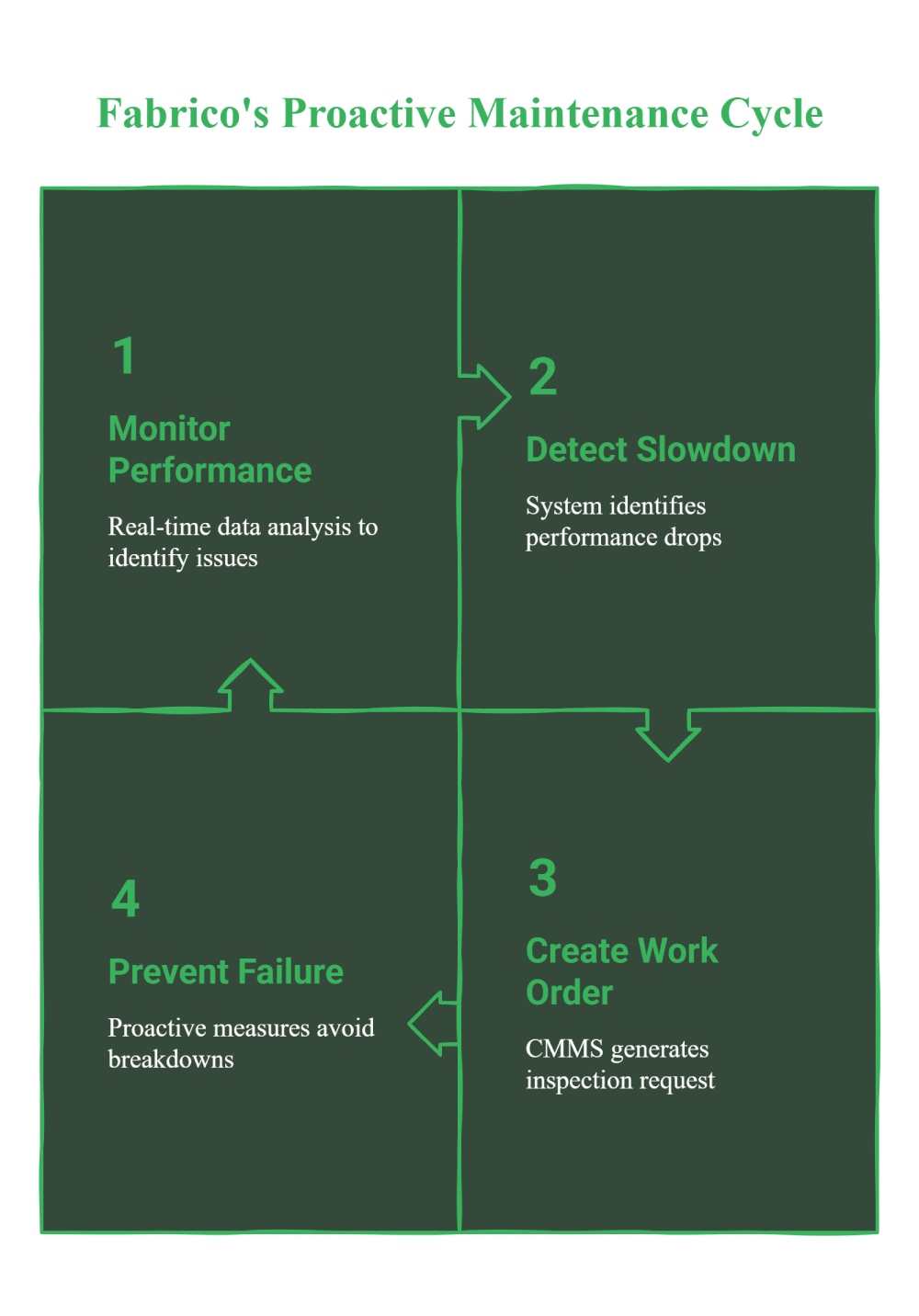

The first step is to implement a system like Fabrico that automatically tracks every cycle and every micro-stop in real-time. This is the powerful diagnostic tool that finally gives you a true, accurate picture of your performance losses. You stop guessing and start seeing the reality on the factory floor.

Step 2: Treat Performance Loss as a Maintenance Trigger (The Cure)

This is the critical connection that most companies miss. A machine that is running slow is often a machine that is about to break down completely.

The Fabrico Workflow: When the OEE system detects that a machine's average cycle time has increased by 5% over the last 24 hours (the diagnosis), it's not just a number on a chart. It's an early warning signal.

This insight allows a manager like Mike to proactively create a maintenance inspection work order in the integrated CMMS (the cure) to investigate the root cause before it leads to a catastrophic failure and a massive, costly availability loss.

Take a live tour with a product expert