Les fonctionnalités sur mesure de Fabrico répondent aux exigences élevées de la production de haute technologie et d'électronique, du suivi des performances à l'analyse intelligente.

Optimisez la visibilité et les performances de votre production :

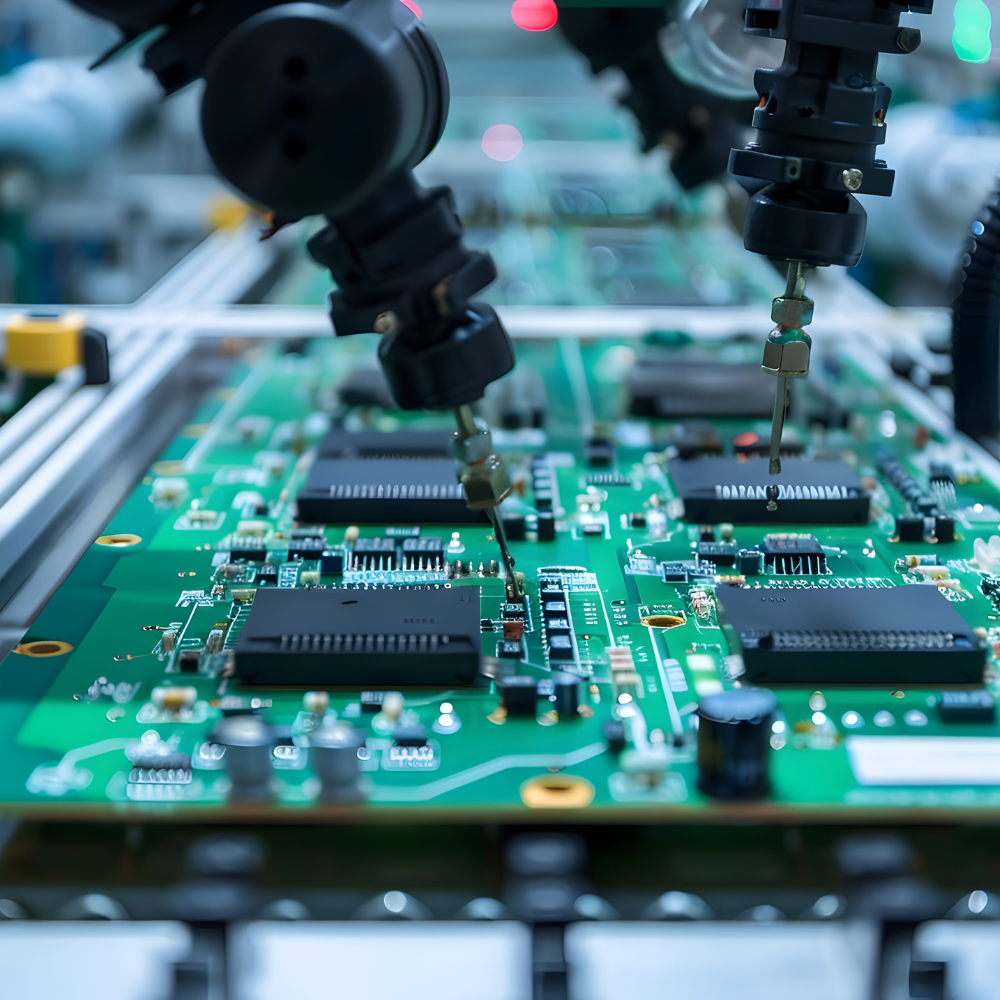

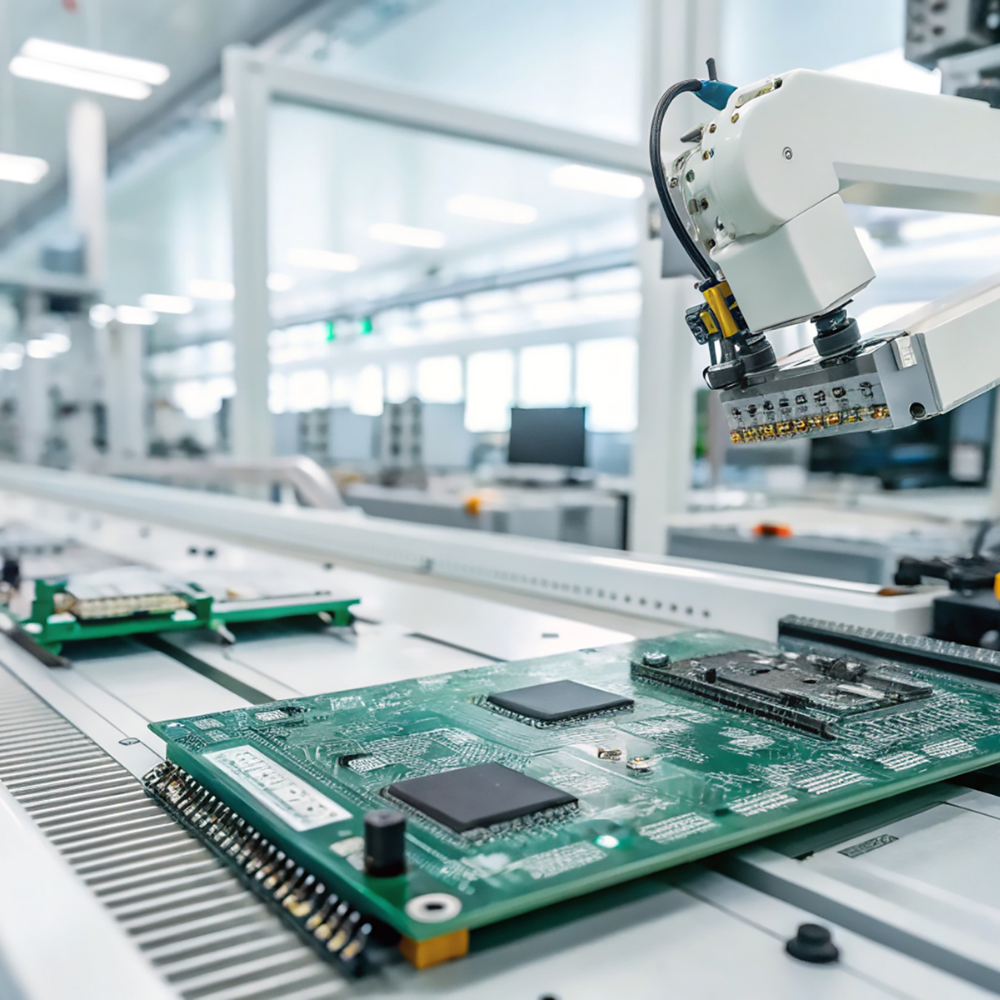

Surveillez vos équipements électroniques critiques, notamment les stocks de composants tels que les cartes de circuits imprimés, les transformateurs et les lignes d'assemblage.

Intégrez des codes QR pour accéder rapidement aux données opérationnelles, aux procédures et aux informations sur les ressources, et minimisez les inefficacités.

Connectez-vous à des capteurs IoT et des automates programmables pour une supervision en temps réel de l'état de la production et optimisez le flux d'assemblage de précision.

Rationalisez vos flux de travail opérationnels :

Automatisez la planification et l'exécution des tâches grâce à des applications mobiles pour iOS et Android, facilitant la prise de décision sur le terrain.

Intégrez des listes de contrôle numériques et un suivi de la conformité pour vous aligner sur des normes telles que les ISO 9001 et 27001.

Mettez en œuvre des stratégies basées sur les données pour améliorer les cycles de vie des processus et favoriser l'amélioration continue dans des environnements dynamiques.

Améliorez vos indicateurs OEE et vos données MES :

Suivez les indicateurs OEE en temps réel grâce à des tableaux de bord intuitifs qui révèlent les opportunités d'amélioration en matière de disponibilité, de performance et de qualité. Déployez des modules d'IA pour identifier les axes d'amélioration de la production, tels que l'optimisation des lignes SMT (technologie de montage en surface) ou des processus de fabrication de circuits imprimés.

Exploitez la vision par ordinateur pour obtenir des informations contextuelles sur les facteurs humains et de processus, au-delà des capteurs traditionnels.

Favorisez la collaboration et la croissance.

Offrez un accès basé sur les rôles aux équipes des opérations internationales, avec une prise en charge multilingue pour une coordination optimale.

Intégrez les systèmes de la chaîne d'approvisionnement pour optimiser la gestion des ressources et la performance des partenaires.

Adaptez votre solution à la croissance de votre entreprise en intégrant des analyses avancées ou des fonctionnalités multisites sans interruption de service.