For years, companies have treated OEE as just a number to track. But a score doesn't fix a broken machine. We believe in a more powerful approach.

Step 1: OEE Software as Your Diagnostic Tool

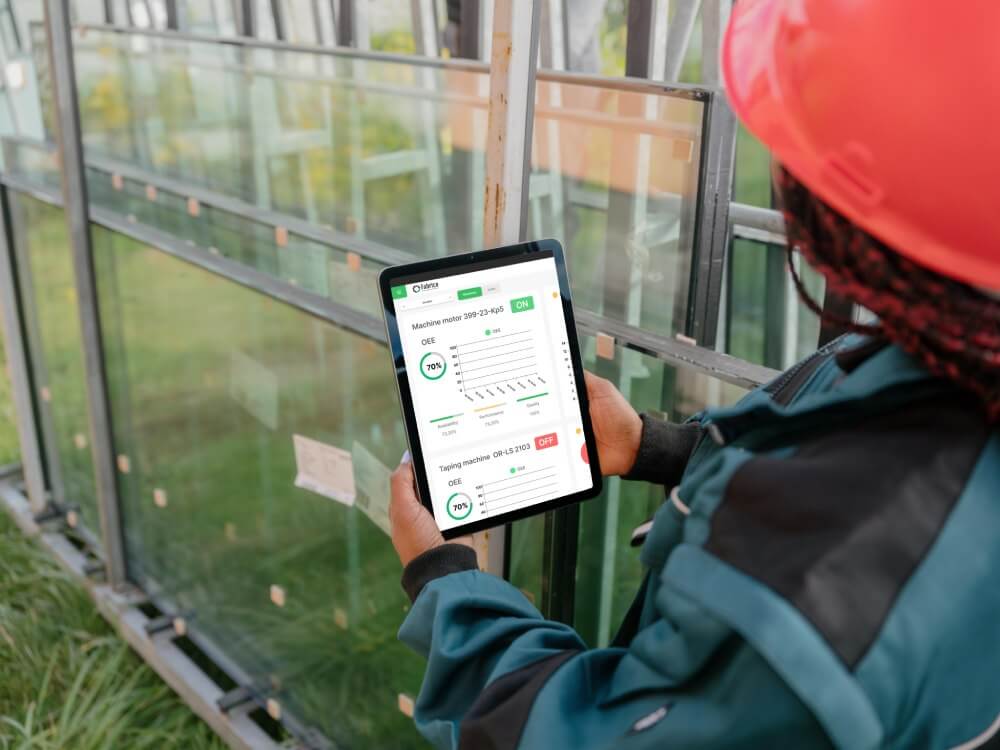

Think of modern OEE software as an MRI for your factory floor. It gives you a clear, real-time picture of your operational health.

It automatically captures data and pinpoints exactly where you're losing money across the Six Big Losses—things like equipment failure, slow cycle times, or lengthy setup and adjustments. It serves up the diagnosis on a silver platter.

Step 2: A CMMS as the Actionable Cure

Once your OEE software flags a 5% availability loss due to a specific packaging line, what happens next? In most plants, it triggers a frantic scramble of phone calls and emails.

This is where a Computerized Maintenance Management System (CMMS) acts as the cure. The CMMS is your "response team." It’s the system that manages work orders, schedules technicians, tracks spare parts, and documents every step of the repair process.

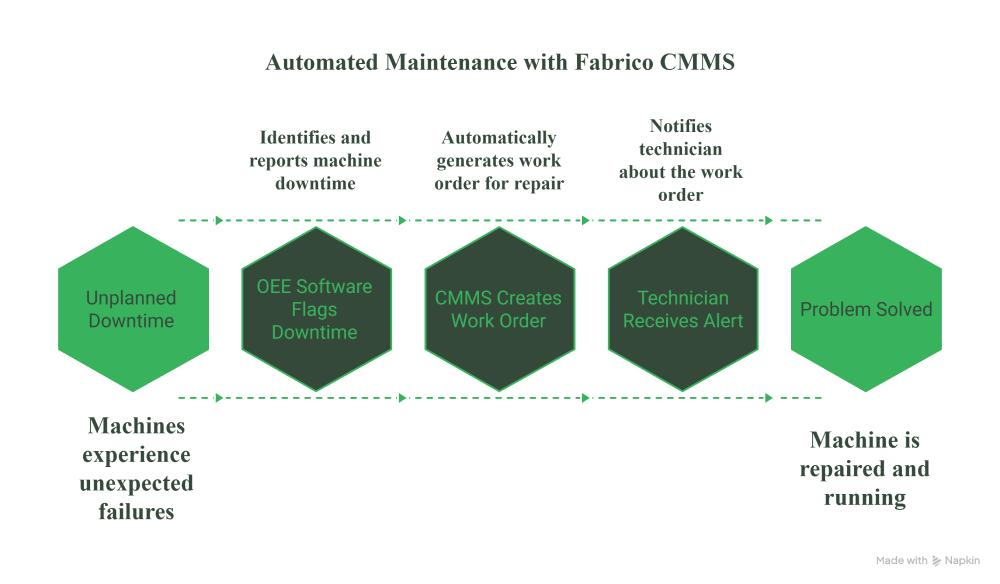

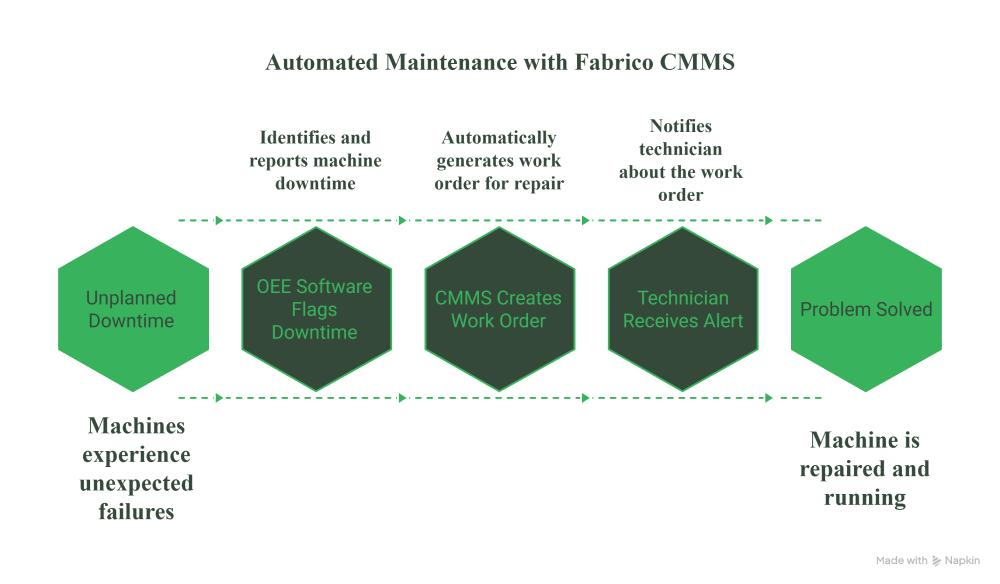

Why an Integrated System is a Game-Changer

The real magic happens when the diagnosis and the cure are part of the same system.

Fabrico's unified platform closes the loop instantly. An OEE alert for unscheduled downtime can automatically trigger a high-priority work order in the CMMS module. The right technician gets the alert on their phone in seconds, with all the data they need.

That’s the difference between knowing you have a problem and actively solving it.