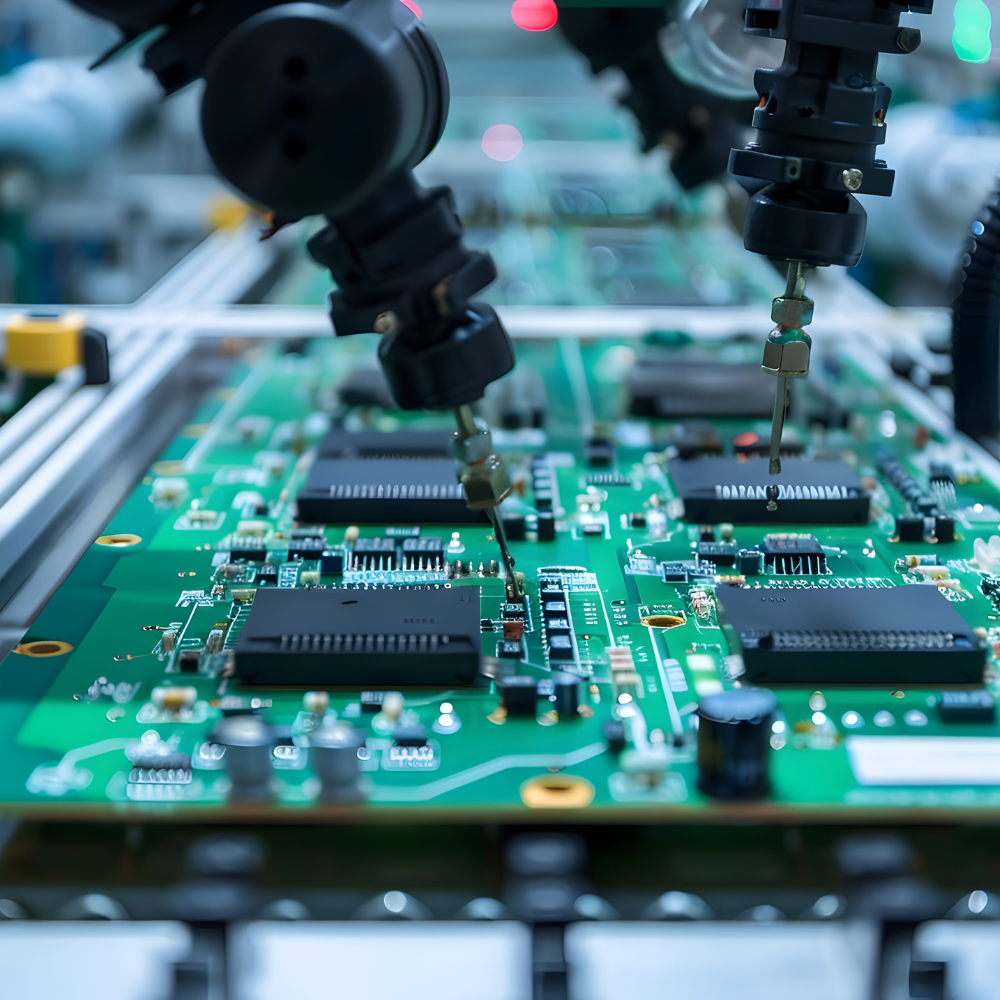

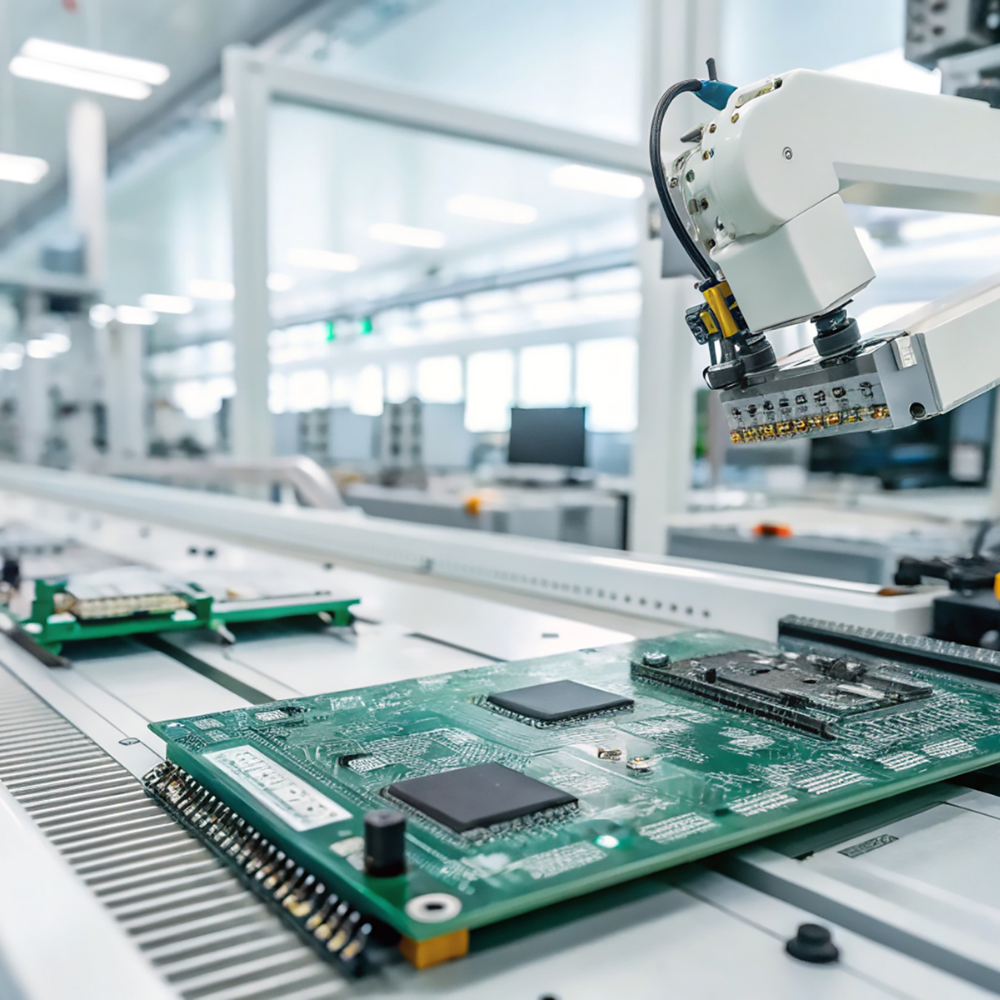

Fabrico to solidna, oparta na chmurze platforma łącząca funkcjonalności MES i OEE, umożliwiająca nadzór nad wszystkimi aspektami produkcji w branży elektronicznej. Spełnia ona specyficzne wymagania branżowe, takie jak szybkie cykle innowacji, złożone łańcuchy dostaw, wymogi regulacyjne oraz dążenie do uzyskania jak najlepszych wskaźników operacyjnych. Dzięki analityce w czasie rzeczywistym, dostępowi mobilnemu i analizom wspomaganym przez sztuczną inteligencję, Fabrico umożliwia producentom maksymalizację OEE – potencjalnie zwiększając je o 15–25% zgodnie z branżowymi standardami – oraz podniesienie ogólnej jakości produkcji.

Nasza platforma obsługuje skalowalność w wielu lokalizacjach, integruje się z systemami ERP, takimi jak SAP lub Oracle, i łączy się z urządzeniami za pośrednictwem sterowników PLC, czujników IoT lub kamer AI. Dzięki temu firmy z branży elektronicznej mogą utrzymywać wyjątkowe standardy jakości, identyfikowalności i elastyczności, jednocześnie rozwijając się globalnie.