Fabrico's attributes are engineered for metal production's stringent necessities, encompassing surveillance to cutting-edge analytical upgrades.

Heighten Visibility and Process Optimization

Direct essential metal resources, from alloy inventories and raw ores to equipment catalogs.

Deploy QR-enabled mechanisms for expedited acquisition of fabrication blueprints, alloy specs, and tool intelligence.

Couple with IoT and PLCs for perpetual process supervision, refining high-intensity forging and milling activities.

Hone Process Coordination

Enable mechanized orchestration and fulfillment of activities using iOS and Android applications, fostering shop-floor responsiveness.

Incorporate virtual guidelines and conformity oversight to satisfy criteria such as ISO 14001 and OSHA standards.

Advocate empirical tactics to prolong operational durations and respond to supply volatilities.

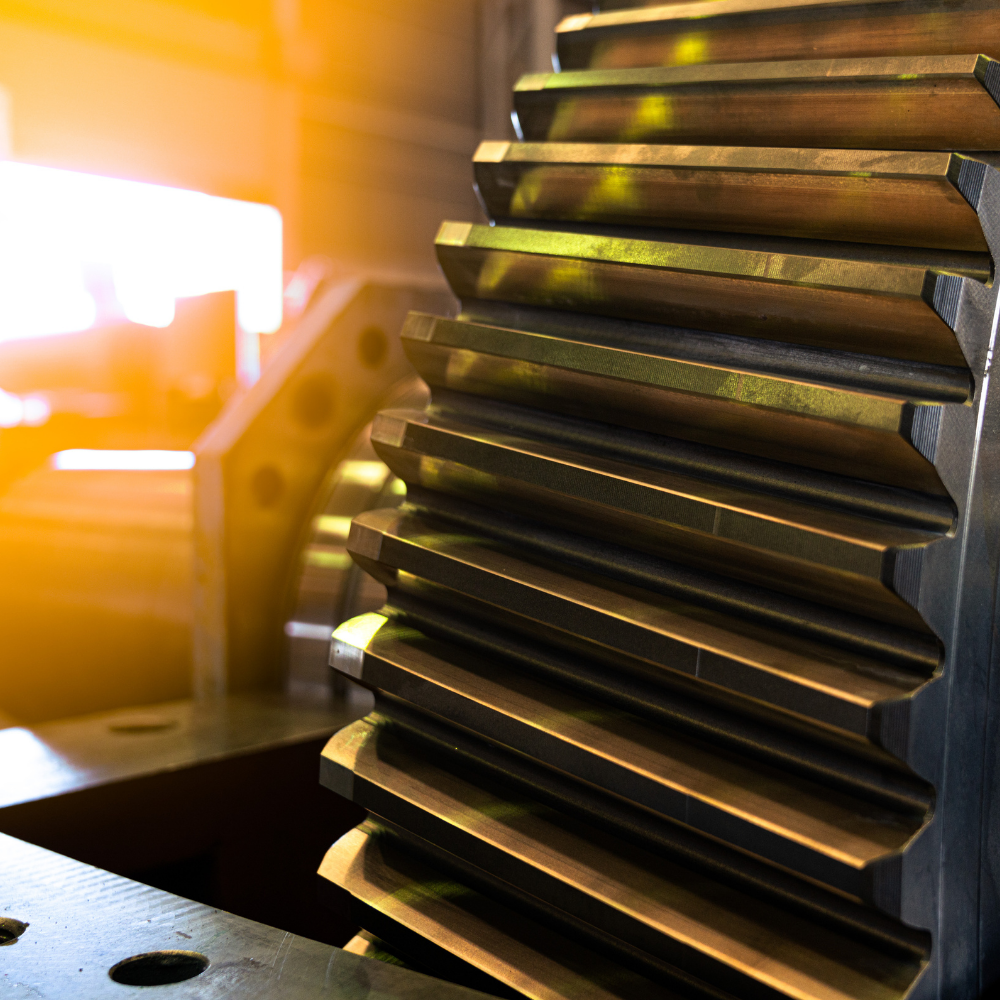

Propel OEE and MES Intelligence

Observe OEE indicators instantaneously on accessible panels, spotlighting uplifts in operational time, velocity, and yield integrity.

Utilize AI instruments to expose enhancements, like in smelting phases or precision machining for tooling.

Employ computer vision for intricate comprehension of personnel and methodological aspects eluding standard detection.

Cultivate Partnership and Development

Furnish tailored entry points for international crews, featuring multilingual setups for harmonized collaboration.

Connect with material chains to hone stock oversight and provider dynamics.

Evolve boundlessly, appending analytical augmentations or facility mergers without hitches.